Aircraft 5 Axis CNC Machining: Precision, Innovation, and Reliability in Aerospace Manufacturing

The Critical Role of 5 Axis CNC Machining in Aerospace

Why Aircraft Demand Unmatched Precision

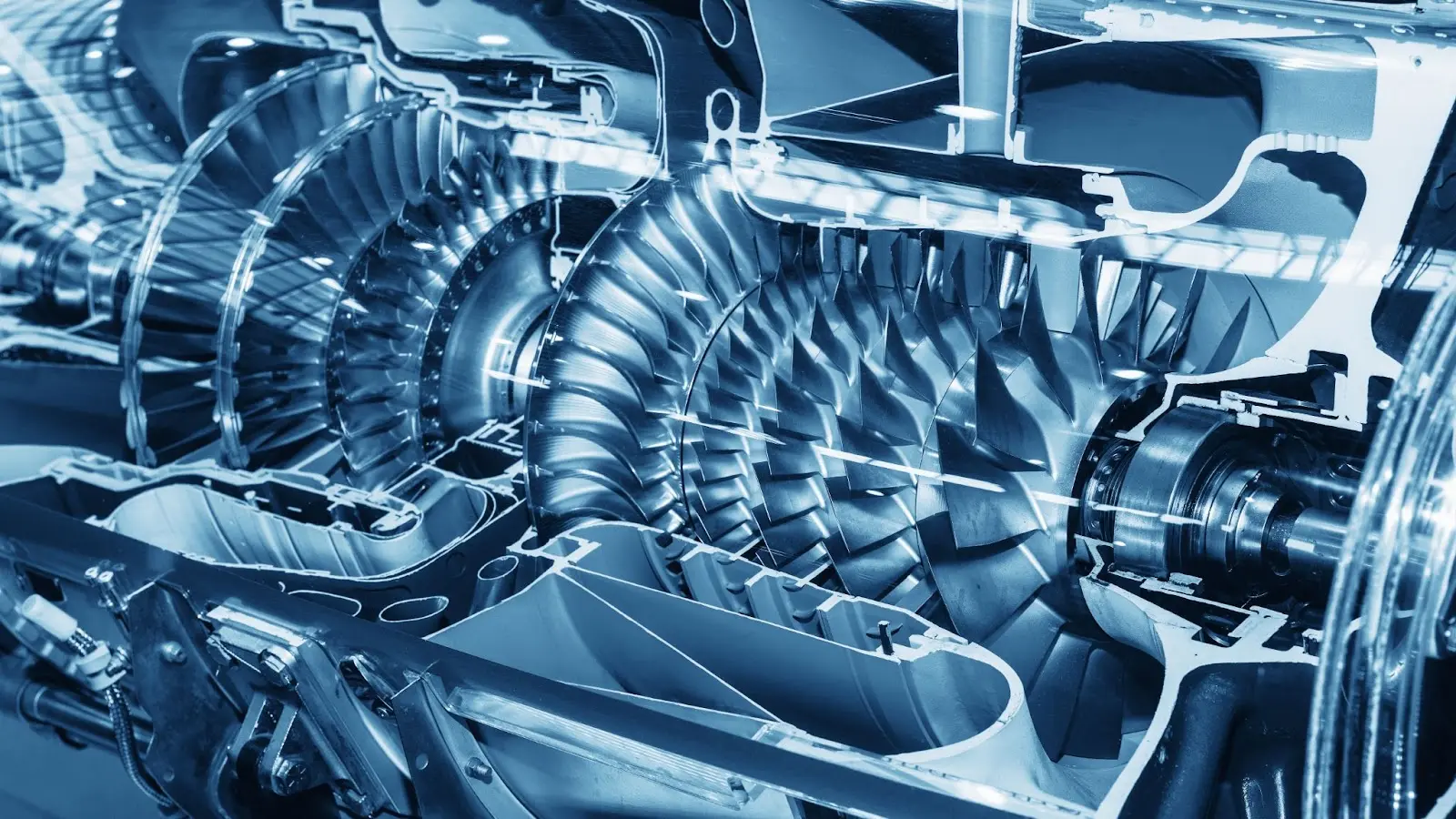

Aircraft components operate under extreme temperatures, pressures, and stresses. Turbine blades, impellers, and wing structures feature compound curves and thin walls that must adhere to flight‑critical tolerances as tight as ±0.001 mm. Any deviation can lead to aerodynamic inefficiencies, increased fuel consumption, or even mechanical failure. Aircraft 5‑Axis CNC Machining provides the micron-level accuracy required to meet these stringent specifications, ensuring each part performs flawlessly at cruise altitudes and beyond.

Advantages of 5 Axis Over Traditional Machining

- Single‑Setup Machining: By articulating the tool along five axes (X, Y, Z, A, and B), complex contours and undercuts are completed in one fixture, eliminating cumulative alignment errors.

- Superior Surface Finishes: Continuous, optimal tool engagement delivers surface roughness values below Ra 0.4 µm, essential for high‑speed airflow applications.

- Reduced Cycle Times: Fewer setups translate directly into faster throughput—sometimes cutting production time by up to 60% compared to 3‑axis workflows.

Key Applications of Aircraft CNC Machining

Engine and Turbine Components

Materials: Inconel 718 and Ti‑6Al‑4V superalloys withstand temperatures exceeding 800 °C in combustion chambers.

Processes:

- 5‑Axis Swiss Screw Machining produces micro‑precision fuel nozzles with diameters under 1 mm and wall thicknesses as fine as 0.2 mm.

- Blisk (Bladed Disk) Production uses simultaneous 5‑axis profiling to mill airfoil geometries directly into a single piece, enhancing structural integrity and reducing assembly complexity.

Structural and Airframe Parts

Parts such as bulkheads, wing ribs, and mounting brackets are often machined from high‑strength aluminum or advanced composites (CFRP). Post‑machining treatments—anodizing for corrosion protection and shot peening for fatigue life—ensure these elements endure cyclical loading during takeoff, flight, and landing.

Why Choose a Specialized Aircraft CNC Machining Supplier?

Expertise in Aerospace Material Challenges

- Titanium Machining: Titanium alloys work-harden rapidly. Precision suppliers employ low‑heat cutting strategies—such as cryogenic cooling—to minimize thermal distortion and extend tool life.

- Composite Machining: CFRP and PEEK demand reduced cutting forces and specialized tooling to prevent fiber pull‑out and delamination, preserving structural performance.

Compliance with Rigorous Industry Standards

- Certifications: AS9100, NADCAP, and ISO 9001 validate quality management systems tailored to aerospace.

- Traceability: From raw material lot numbers through First Article Inspection Reports (FAIR), every batch is documented to meet OEM and regulatory requirements.

Advanced Technologies in Precision Aircraft Machining

Multi‑Axis Swiss Screw Machining

By integrating live tooling on multi‑spindle Swiss-style CNC machines, suppliers can produce miniature connectors, fasteners, and electrical pins with sub‑millimeter features in a single pass, achieving tolerances of ±0.002 mm.

Hybrid Manufacturing for Prototyping

Combining 5‑Axis CNC Machining with Direct Metal Laser Sintering (DMLS) allows the production of topology‑optimized parts—such as eVTOL structural mockups—that integrate internal cooling channels and reduce weight by up to 30% without compromising strength.

Spotlight on Precision Aircraft Machining Companies

Case Study – Precision Aircraft Machining Co Inc

With over 40 years in aerospace, this ITAR‑registered, ISO 13485‑certified firm specializes in medical‑grade flight components. They leverage advanced 5‑axis Swiss screw centers to supply medical aircraft systems with peerless precision and traceable documentation.

Great Light’s Capabilities as an Aircraft CNC Machining Supplier

- Machine Fleet: DMG Mori NHX 6300 and Mazak VARIAXIS 5‑axis centers handle parts up to 1.2 m in any orientation.

- One‑Stop Services: Precision part machining, finishing (anodizing, plating), assembly, and global logistics deliver turnkey solutions for OEMs and Tier‑1 suppliers.

Material Selection for Aircraft Parts Machining

Titanium – The Backbone of Aerospace Engineering

Grade 5 (Ti‑6Al‑4V) is prized for its exceptional strength-to-weight ratio. Advanced suppliers employ cryogenic machining and high-pressure coolant to reduce tool wear and achieve consistent surface integrity.

Composites and High‑Performance Plastics

CFRP excels in radomes and wing fairings for stealth and weight savings, while PEEK components withstand high‑heat interiors, such as cabin ovens and avionics housings.

Quality Assurance in Aircraft Machining Services

Inspection Technologies

- CMM & Laser Scanning: Validate 3D geometries against CAD models within microns.

- Surface Roughness Testing: Ensures aerodynamic criteria are met for airflow-critical surfaces.

Certifications and Documentation

Every batch includes FAIR, PPAP submissions, and material certificates, guaranteeing compliance for aerospace certification audits.

Custom Solutions for Unique Aerospace Needs

Non‑Standard Part Production

Legacy aircraft often require hydraulic manifolds no longer in production. Suppliers reverse-engineer these parts via 3D laser scanning, recreating CAD models and delivering drop-in replacements.

Rapid Prototyping for Next‑Gen Aircraft

Low‑volume runs of UAV and eVTOL prototypes with lead times under two weeks empower engineering teams to iterate flight‑critical designs swiftly.

Sustainability in Aircraft CNC Machining

Reducing Waste with Adaptive Machining

AI‑driven toolpath algorithms optimize cutting strategies to minimize scrap rates—crucial when working with superalloys that cost hundreds of dollars per kilogram.

Recycling Titanium Swarf

Closed‑loop collection and remelting of titanium chips reduce raw material expenditures by up to 15% and lower the carbon footprint of production.

How to Partner with a Reliable Aircraft Machining Supplier

Supplier Vetting Process

- Checklist: Verify certifications, review machine inventories, and examine case studies.

- On‑Site Audits: Conducted at major aerospace hubs—Wichita, Toulouse, Seattle—to assess shop-floor rigor.

Navigating Global Logistics

Just‑In‑Time delivery partnerships with freight carriers support OEMs like Boeing and Airbus, ensuring parts arrive precisely when needed to maintain production schedules.

FAQs: Addressing Common Queries

What Makes Swiss Screw Machining Ideal for Aircraft Parts?

Live tooling and simultaneous multi‑axis control enable sub‑millimeter features for fuel system pins and sensor housings in a single operation.

Can Suppliers Handle Low‑Volume, High‑Mix Orders?

Flexible pallet‑changer systems allow quick reconfiguration for prototypes and legacy part batches, eliminating the cost penalties of frequent changeovers.

How Do Suppliers Ensure IP Protection?

Secure data transfers via SSL encryption, strict NDA agreements, and on‑premise file control systems protect proprietary designs throughout the manufacturing lifecycle.

Future Trends in Aircraft 5 Axis CNC Machining

Smart Factories and IoT Integration

Real‑time monitoring of spindle load, tool wear, and energy consumption optimizes uptime and maintenance schedules, moving towards fully autonomous machining cells.

Lightweighting with Advanced Alloys

Scandium‑aluminum alloys and hybrid additively manufactured structures are poised to reduce aircraft weight by an additional 10–15%, unlocking new efficiencies in fuel consumption.

Conclusion

5 axis CNC machining is the linchpin of modern aerospace manufacturing—delivering micron-level accuracy, complex geometries, and sustainable production methods. By partnering with specialized suppliers like Great Light CNC Machining, aircraft OEMs and Tier‑1 integrators secure end‑to‑end solutions that guarantee flight‑critical parts are delivered on time, on spec, and on budget.

Ready to Elevate Your Aerospace Components?

👉 Request a Quote from Great Light CNC Machining