CNC MACHINING PTE. LTD excels in fast prototypes and low volume production with state-of-the-art 5-axis and 4-axis CNC. We ensure tight tolerances, on-time delivery, and quick quotes.

One of the Best Rapid Prototyping Companies from China, CNC MACHINING PTE. LTD is an ISO GB/T 19001-2016/IS09001:2015 certified manufacturer and is an excellent choice for custom metal and plastic parts. Whether you need a complex part made from a 3D design or a finished product for a high-level conference presentation, we can quickly produce prototypes and parts in a matter of days using 3-, 4- and 5-axis CNC machining.

Affordable Price

Precision and Accuracy

Consistent Quality

Increased Productivity

Active client with positive reviews

We provide turnkey solutions for new products from concept to rapid prototyping and low-volume manufacturing, CNC machining, die casting, post-processing to assembly.

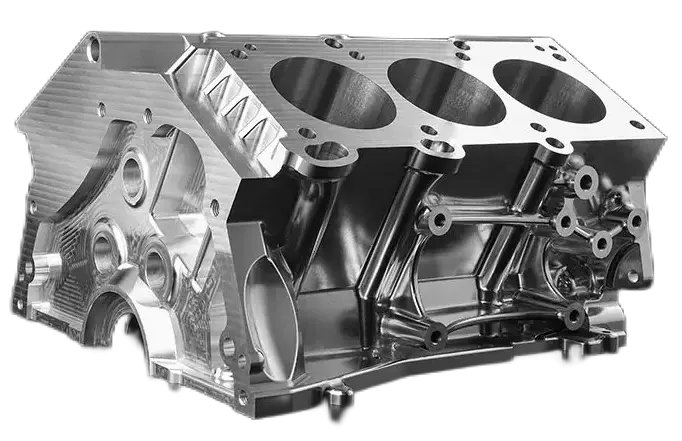

For complex geometric machining parts, our 5-axis CNC machining service provides unparalleled flexibility and speed.

High efficiency, heavy cutting capability, simple operation, high precision and good surface effect.

The high-precision, high-efficiency and high-flexibility processing capabilities can meet the processing requirements of complex shapes and precision.

CNC Milling & Turning services that support rapid prototyping design and production needs, High precision, good surface finish and high efficiency.

CNC MACHINING PTE. LTD’s quality service policy: Keep improving, craft each product with craftsmanship, ensure excellent quality and efficient service, and meet the diverse needs of customers.

Here’s what our satisfied customers have to say about how we met their needs, Their words speak louder than ours.

Designer

Thrilled with the fast CNC production and top-notch parts! Excellent service and flawless surface finishes. Great job!

Business Owner

The level of expertise of their engineers and their ability to complete these projects in a short period of time is commendable and worthy of recognition.

Designer

The results were outstanding. We were manufacturing a large housing component for an aerospace application with extremely complex hole geometry.

Business Owner

Had a great experience with CNC MACHINING PTE. LTD! Alice’s communication and dedication were excellent, and the product quality exceeded expectations. Highly recommend!

Businessman

They handled all aspects of this turnkey project quickly, professionally, and cost-effectively. We look forward to working with them again on future projects.

Business Owner

This is the most professional CNC service provider I have ever worked with and it has been a pleasure to work with them since day one. I have been in procurement for over 15 years and have worked on many projects with suppliers from all over the world.

Business Owner

I have been with them from the beginning and have seen this progress and I am very satisfied. Thanks again to all of you and everyone else behind the scenes for doing a great job.

Business Owner

CNC MACHINING PTE. LTD can handle your CNC machining whether you need a few parts or over 10,000 end-use units. Check out the variety of custom CNC services we offer to take your designs from concept to reality quickly and accurately.

Firstly, our team will inspect all incoming material. Secondly, our QC team will inspect parts during machining and the finished parts after all machining completed.

Please contact us via our online platform or Email, and send us your drawings of 2D and 3D (.STEP or .IGE file) and detail requirements. Then we will analyse your part design and submit competitive price to you.

Yes, we can support making prototypes with cnc machining process for your assembly and testing before high volume production.

We normally ship samples via DHL, UPS or FedEX . For the shipping of mass production order, we usually arrange it by sea or by air.

Our own internal processing capabilities: Five-Axis CNC 16 Units, Four-Axis CNC 12 Units, Three-Axis CNC 27 Units, CNC Milling & Turning 16 Units. If you have larger processing needs, we can also meet them.

Our engineering and sales teams will provide one-on-one quote support for your project. Typically, for similar parts, CNC lathes cost 15% less to machine than standard 3-axis CNC milling. In contrast, the cost of 5-axis machining increases, continuous 5-axis CNC milling typically costs over 20% higher than an indexed 5-axis machine (also referred to as 3+2 milling), and about double that of a standard 3-axis mill. To achieve the most cost-effective CNC machined parts, larger production runs are recommended to spread the cost of machine setup.

Maximum Dimensions (3-axis milling): 1500*800*300mm, 1270×508×635 (mm).

Maximum Dimensions (5-axis milling): 4000*400*150mm, 750x1150x550mm,

600*600*600mm, 500*500*450mm, 500*310*200mm,

Worktable Diameter Φ400 mm. All can be processed, and larger sizes can also be consulted by engineers

5-axis machines enable complex CNC machining by increasing the range of motion and positioning of cutting tools. This increased flexibility allows for greater precision and accuracy, resulting in more complex designs that are difficult or impossible to achieve with traditional manufacturing methods.

Additionally, 5-axis machining eliminates the need for multiple machines to create complex parts, saving time and cost in the manufacturing process. For businesses that adopt 5-axis machining, this can result in faster turnaround times, increased efficiency, and greater competitiveness.

Once the machining process is complete, the CNC parts surface will have slight visible tool marks, called “as-machined” or “as-milled” surface finish. Machined surface roughness (Ra) is standardized at 1.6-3.2 μm, and surface finish requirements can be increased to 0.8-1.6 μm or higher at 0.2-0.8 μm, however, this will require more operating time and higher costs.

Impressed by the fast delivery and top-quality CNC parts! Your team's efficiency and personalized service were outstanding. Excited for future collaborations!