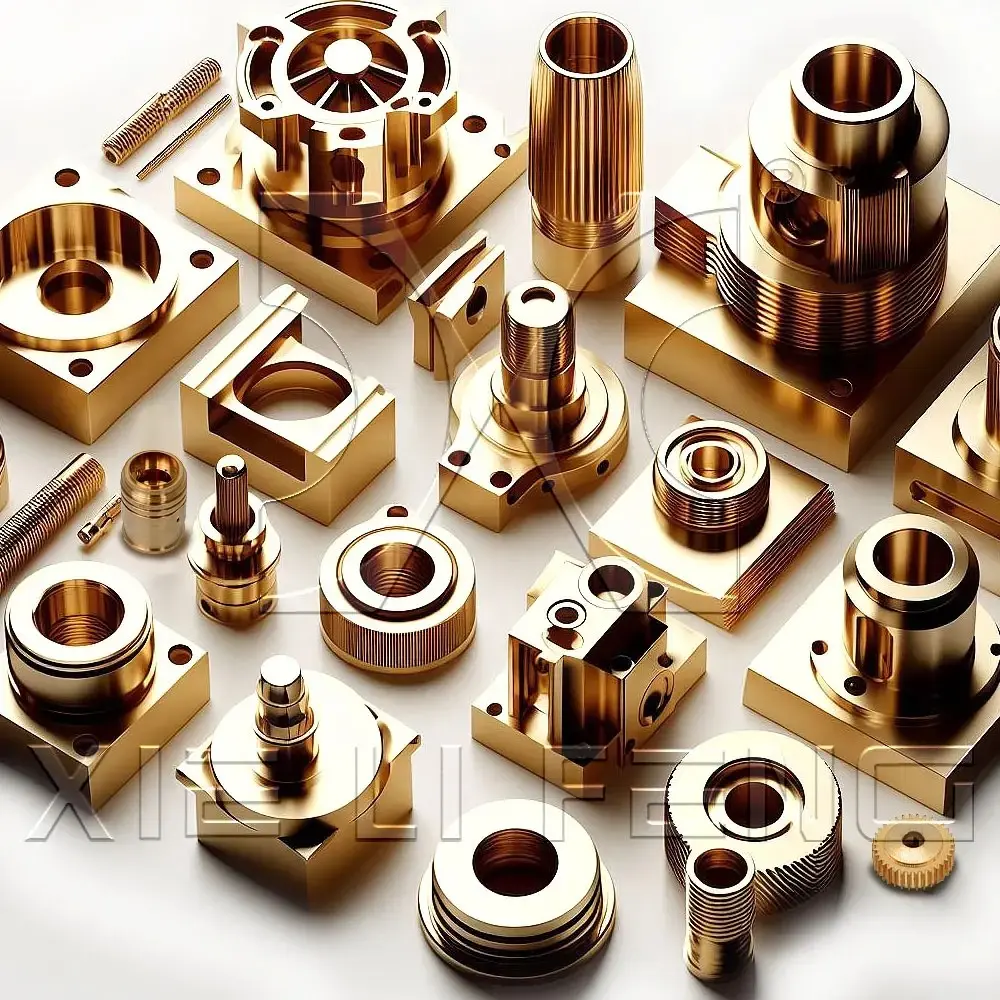

In the competitive world of precision manufacturing, CNC machining has revolutionized the way industries design and produce complex parts. Advanced CNC machining companies like Advance CNC Machining leverage CNC machine services to provide high-quality, precise, and cost-effective solutions across a wide range of applications. This article explores how Advance CNC Machining uses CNC machine services to optimize their production processes, improve ROI, and meet the demands of industries with tight tolerances.

Advanced Machining Technology

The core of Advance CNC Machining’s success lies in its investment in advanced machining technology. CNC machines, which are controlled by a computer program, allow for precise, repeatable operations with minimal human intervention. At Advance CNC Machining, the focus is on using the most sophisticated equipment available to ensure that every part meets exacting standards.

Our Makino 4- and 5-axis machining centers are examples of the cutting-edge technology we use. These high-speed, high-precision machines allow for intricate designs and complex geometries that would be impossible or highly cost-prohibitive with traditional manufacturing methods. With robotic loaders and pallet systems, we enable “lights-out” production, meaning our machines can operate autonomously, 24 hours a day, without the need for human supervision.

Benefits of CNC Machining Services

CNC machining services offer a wide range of benefits for industries that require high-precision parts. Some of the key advantages of outsourcing CNC machining services include:

1. Precision and Accuracy

CNC machining ensures exceptional accuracy and repeatability. With tolerances as tight as 0.001mm, CNC machines can produce parts with remarkable precision, which is crucial for industries like aerospace, medical devices, and automotive.

2. Customization and Flexibility

Whether you need custom prototypes or low-volume production runs, CNC machining services offer a high degree of flexibility. Designs can be adjusted on-the-fly, making it easy to accommodate changes in client specifications or last-minute design adjustments.

3. Faster Turnaround Times

CNC machines can be programmed to execute a variety of operations in quick succession. This efficiency drastically reduces the time required to produce parts, which in turn reduces lead times and speeds up the overall production process.

4. Cost-Efficiency

While initial setup costs for CNC machining may seem high, they offer substantial long-term cost savings. The elimination of tooling costs, lower material waste, and the ability to optimize production schedules result in overall savings for businesses.

5. Consistency and Repeatability

Once a CNC machine is programmed, it can produce parts with identical dimensions and tolerances, ensuring that every piece meets the same high standards. This consistency is particularly valuable in industries where part uniformity is critical.

How CNC Machining Services Improve Your Production Process

CNC machining services can significantly enhance your production processes in several ways:

Streamlined Production

By automating many aspects of manufacturing, CNC machining reduces the need for manual intervention, allowing for smoother operations and fewer errors. With advanced technologies like robotic loading systems and automated pallet systems, production can run 24/7, even during off-hours, contributing to higher productivity.

Reduced Lead Times

The ability to program CNC machines for multiple operations means that tasks that would traditionally take several steps or require different machines can now be completed in a single setup. This drastically reduces production lead times and accelerates the delivery of finished products to customers.

Lower Operating Costs

CNC machining services are highly efficient, reducing the need for manual labor and minimizing human error. This leads to lower operating costs, as fewer resources are required to complete each project. Additionally, the precision of CNC machining minimizes material waste, making production more cost-effective.

Advanced Machining Technology to Improve ROI

For machine shops, maximizing ROI (Return on Investment) is a top priority. At Advance CNC Machining, we understand that ROI is not just about the cost of machinery or the price per part, but also about how effectively technology can improve productivity, reduce waste, and increase overall production efficiency.

Here’s how we improve ROI using advanced CNC machining:

- Increased Efficiency and Productivity: Automation allows CNC machines to run continuously without human supervision, increasing throughput and allowing shops to handle larger volumes without adding labor costs.

- Minimized Waste: CNC machining’s precision means less material waste and fewer defects, reducing scrap and rework costs.

- Lower Labor Costs: Automation and advanced machinery mean fewer operators are needed, which leads to a reduction in labor costs.

- Faster Turnaround: CNC machining speeds up the production process, which leads to quicker delivery times and a faster time to market.

- Scalability: Whether a company needs to produce a handful of parts or thousands, CNC machining can scale to meet demand. It allows for easy adaptation to changes in production volume without significant additional investments in equipment or manpower.

Our Team

At Advance CNC Machining, we recognize that the quality of our products is directly tied to the expertise of our team. We hire only highly skilled professionals who are committed to delivering exceptional service and quality. Our machinists undergo continuous training to stay ahead of the latest machining technologies and best practices. This expertise ensures that every project, no matter how complex, is executed to the highest standards.

Technology and Automation

As part of our commitment to staying at the forefront of machining technology, we use sophisticated automation systems that ensure consistent quality and repeatable results 24 hours a day. Robotic loaders, pallet systems, and automated tool changers enable our machines to operate autonomously, which maximizes productivity and reduces costs.

Our investment in Coordinate Measuring Machines (CMMs), optical scanning, and optical imaging equipment further supports our commitment to precision. These tools help ensure that every part we produce meets the required specifications and quality standards.

High Standards

Advance CNC Machining adheres to rigorous standards in every phase of the manufacturing process. Whether we’re working on aerospace parts that require precise tolerances or producing custom medical devices, we ensure that our products meet the highest industry standards. We’re accustomed to working with tight tolerances and complex geometries, making us a trusted partner for demanding industries.

Trade Record

We pride ourselves on our exceptional track record. Our success rate for delivering products on time and to specification is a testament to our commitment to quality and customer satisfaction. Over the years, we’ve earned the trust of customers in industries ranging from aerospace and medical devices to automotive and electronics.

Equipment

Our state-of-the-art Makino 4- and 5-axis machining centers are the backbone of our operations. These high-speed machines are capable of executing highly complex tasks with precision, whether it’s milling, drilling, or turning. We also rely on advanced measuring systems like CMMs to ensure the highest quality.

Why You Can Count on Us

Advance CNC Machining is committed to providing the highest level of service and precision. Our customers rely on us because we consistently meet deadlines, deliver quality products, and ensure repeatable, reliable results. Here are some reasons why you can trust us with your CNC machining needs:

- 99.3% On-Time Delivery: We take deadlines seriously and strive to meet every customer requirement on time.

- Fast Quotes: We provide comprehensive quotes within 48 hours, ensuring you have the information you need to move forward quickly.

- Dedicated Account Managers: Our team is available to answer your questions and handle any issues that arise, ensuring a smooth experience.

- Reliable Service: We do what we say we will do—no surprises.

5 Advantages of Outsourcing to CNC Machining Companies

Outsourcing CNC machining offers several key advantages:

- Expertise: CNC machining companies have specialized knowledge and experience, enabling them to deliver superior quality parts.

- Cost Savings: By outsourcing, you avoid the upfront investment in machinery and labor.

- Scalability: CNC machining can easily scale to meet fluctuating production needs.

- Improved Quality: With automated systems and high-precision equipment, outsourcing ensures the highest quality products.

- Time Savings: Outsourcing CNC machining services allows you to focus on your core business while professionals handle the production process.

Applications of CNC Machining

CNC machining is used across a broad range of industries, including:

- Aerospace: Precision components for aircraft and space exploration.

- Medical Devices: Custom parts made from biocompatible materials.

- Automotive: Performance parts for cars and trucks.

- Electronics: Custom enclosures, connectors, and circuit board components.

- Industrial Equipment: Reliable parts for heavy machinery and equipment.

Conclusion

Advance CNC Machining is your trusted partner for all CNC machining services. With state-of-the-art equipment, skilled technicians, and a commitment to quality, we ensure precision and efficiency in every project. Whether you need custom parts for aerospace, medical devices, or industrial applications, we deliver high-quality results on time and within budget. Our focus on advanced technology, automation, and high standards makes us a leading choice for all your CNC machining needs.