Introduction

In today’s competitive manufacturing environment, Precision Titanium Machining Using 5-Axis Technology stands out as a transformative approach that meets the rigorous demands of industries such as aerospace, medical, and high-performance automotive. As a leading CNC Machining Manufacturer, Great Light leverages advanced 5-Axis CNC Machining systems to deliver impeccable Titanium Machining and CNC Machining Services. This article explores the inherent advantages of 5-axis technology, its impact on precision titanium machining, and how our innovative, one-stop post-processing solutions ensure optimal quality and cost-efficiency for custom metal parts.

The Challenges of Titanium Machining

Material Properties and Machining Complexity

Titanium, known for its exceptional strength-to-weight ratio and corrosion resistance, poses unique machining challenges. Its low thermal conductivity and high chemical reactivity often result in rapid tool wear and dimensional inaccuracies. Overcoming these obstacles demands not only advanced machine tools but also highly specialized CNC Machining processes. Precision machining of titanium requires controlled cutting parameters and state-of-the-art cooling systems to maintain dimensional stability and surface integrity.

Demanding Applications in High-Performance Industries

Industries such as aerospace, defense, and biomedical engineering require components with extremely tight tolerances. Precision Titanium Machining is critical when producing parts that must endure extreme conditions while retaining structural integrity. Here, the use of 5-Axis Technology enables complex geometries and intricate detailing that conventional machining methods simply cannot achieve. The ability to machine from multiple angles minimizes repositioning errors and guarantees high-quality finishes, ensuring that every part meets stringent industry standards.

The 5-Axis Advantage in Titanium Machining

Enhanced Precision and Flexibility

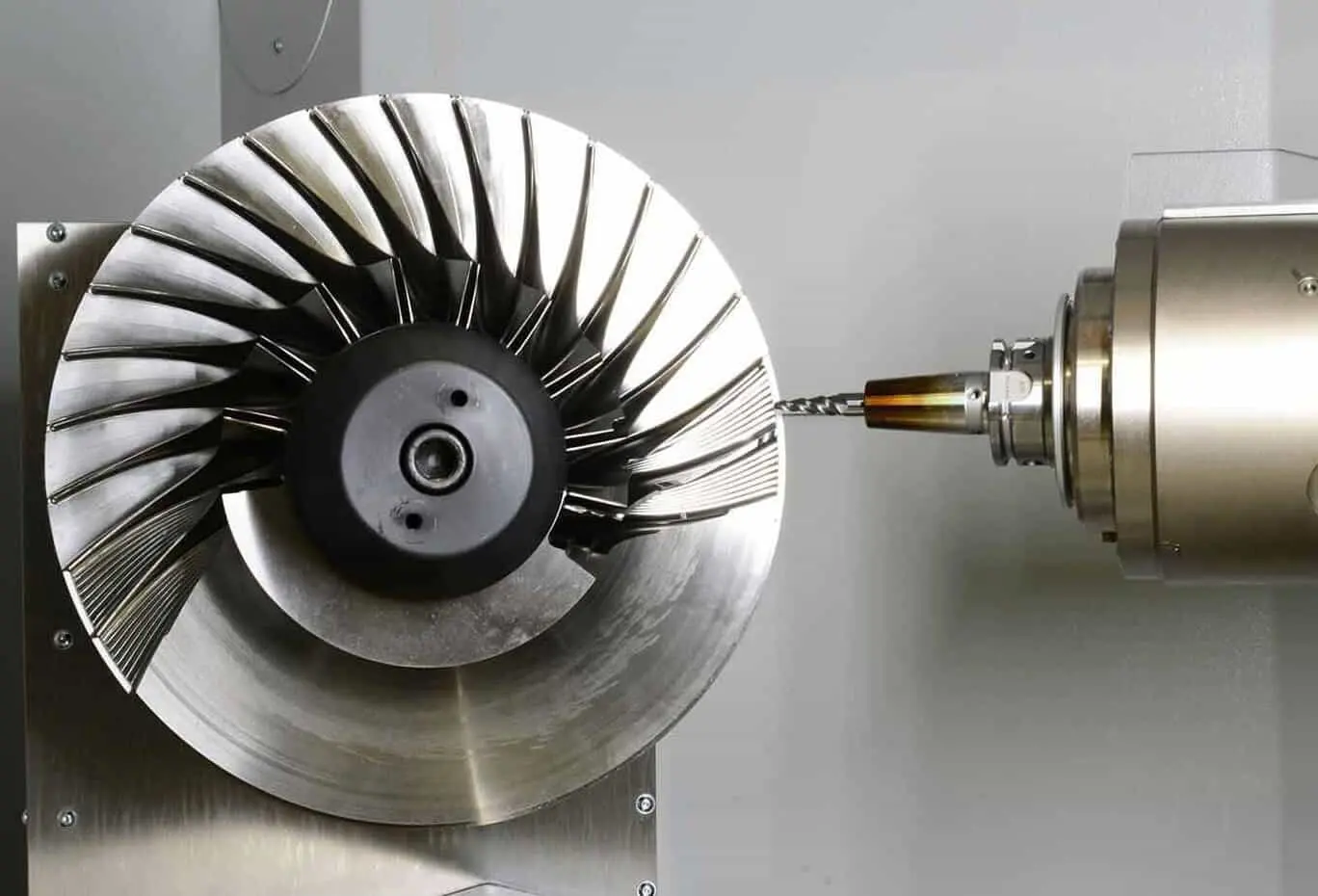

5-Axis CNC Machining revolutionizes the traditional machining process by enabling simultaneous multi-axis movement. This capability allows manufacturers to achieve complex geometries and intricate contours in a single setup. By reducing the need for multiple setups, Precision Titanium Machining Using 5-Axis Technology not only minimizes errors but also shortens production cycles. This translates into improved accuracy, lower scrap rates, and ultimately, a competitive edge in high-precision production environments.

Superior Surface Finish and Reduced Post-Processing

One of the key benefits of 5-Axis Technology is its ability to deliver superior surface finishes directly from the machining process. With fewer tool passes and optimized cutting paths, manufacturers can significantly reduce the need for secondary finishing processes. This results in lower overall production costs and faster turnaround times—an essential factor for industries where time-to-market is critical. Moreover, high-quality surface finishes improve part performance, particularly in applications where aerodynamics or biocompatibility is a factor.

Complex Geometries with Single Setup Efficiency

Traditional 3-axis machines often require multiple setups to machine parts with complex geometries, which increases the risk of misalignment and dimensional variation. In contrast, 5-Axis CNC Machining offers the efficiency of machining under a single setup. This ensures that every facet of the component is precisely controlled and accurately finished, making it the ideal choice for customized precision titanium parts. The ability to handle intricate designs and challenging materials elevates Precision Titanium Machining to a new standard in manufacturing excellence.

Great Light’s Expertise in CNC Machining Services

Advanced 5-Axis CNC Machining Equipment

At Great Light, our commitment to innovation is evident in our state-of-the-art 5-Axis CNC Machining facilities. We have invested in cutting-edge equipment that not only meets but exceeds industry standards for precision and efficiency. This advanced machinery is central to our capability of delivering complex Titanium Machining projects with unparalleled accuracy. Our highly skilled technicians and engineers continuously optimize machining parameters to ensure that every part produced adheres to strict quality guidelines.

One-Stop Post-Processing and Finishing Solutions

Beyond machining, Great Light offers a complete suite of post-processing services. This one-stop solution includes deburring, polishing, and various finishing techniques that further enhance the performance and appearance of the machined parts. Our integrated approach ensures that from the initial rough cut to the final quality check, every step is managed with scientific rigor and attention to detail. Clients benefit from reduced lead times and cost efficiencies, reinforcing our reputation as a trusted CNC Machining Manufacturer.

Quality Assurance and Scientific Rigor

Quality is the cornerstone of our CNC Machining Services. Great Light employs a robust quality management system that includes real-time monitoring, advanced metrology, and continuous process improvement. Our adherence to international quality standards and our scientific approach to problem-solving make us a leader in Precision Titanium Machining. We pride ourselves on delivering parts that not only meet but often exceed customer expectations, cementing our position as the first choice for advanced 5-Axis CNC Machining.

Process Innovations and Industry Insights

Customized Solutions for Diverse Industries

The versatility of 5-Axis Technology allows us to tailor our machining processes to the specific needs of each industry. Whether it is high-precision aerospace components, critical medical implants, or robust defense equipment, our solutions are designed to address unique challenges.

Sustainability and Efficiency in Modern Manufacturing

In addition to precision and quality, modern manufacturing demands sustainability. Our advanced CNC Machining processes are designed to optimize material usage and reduce waste. Through intelligent design and process innovation, we enhance energy efficiency and minimize environmental impact. This commitment not only supports global sustainability goals but also offers clients a competitive advantage in terms of cost savings and corporate responsibility.

Interactive Elements & FAQ

Frequently Asked Questions

Q: What makes 5-axis technology superior for titanium machining?

A: The multi-axis movement allows for machining complex geometries in a single setup, enhancing precision and reducing post-processing requirements. This is critical for high-performance parts in demanding industries.

Q: How does Great Light ensure quality in precision titanium machining?

A: We integrate advanced 5-axis CNC machining with rigorous quality assurance protocols, including real-time monitoring and comprehensive metrology, to ensure every part meets strict standards.

Q: Can your services accommodate both small and large production runs?

A: Yes, our flexible manufacturing processes are designed to handle a wide range of production volumes without compromising on precision or quality.

Conclusion: The Future of Precision Titanium Machining

In conclusion, Precision Titanium Machining Using 5-Axis Technology represents a significant leap forward in the field of CNC Machining Services. The integration of advanced 5-axis capabilities not only improves machining precision and surface finish but also offers enhanced efficiency and sustainability. Great Light’s expertise and commitment to innovation make us the ideal partner for customized titanium parts, setting new industry benchmarks in quality and performance.

Now is the time to embrace the future of titanium machining. Customize your precision titanium parts with our advanced 5-Axis CNC Machining solutions and experience the difference that scientific rigor, quality assurance, and industry-leading technology can make.