Precision CNC Machining: Your Guide to CNC Machined Parts

What Is Precision CNC Machining?

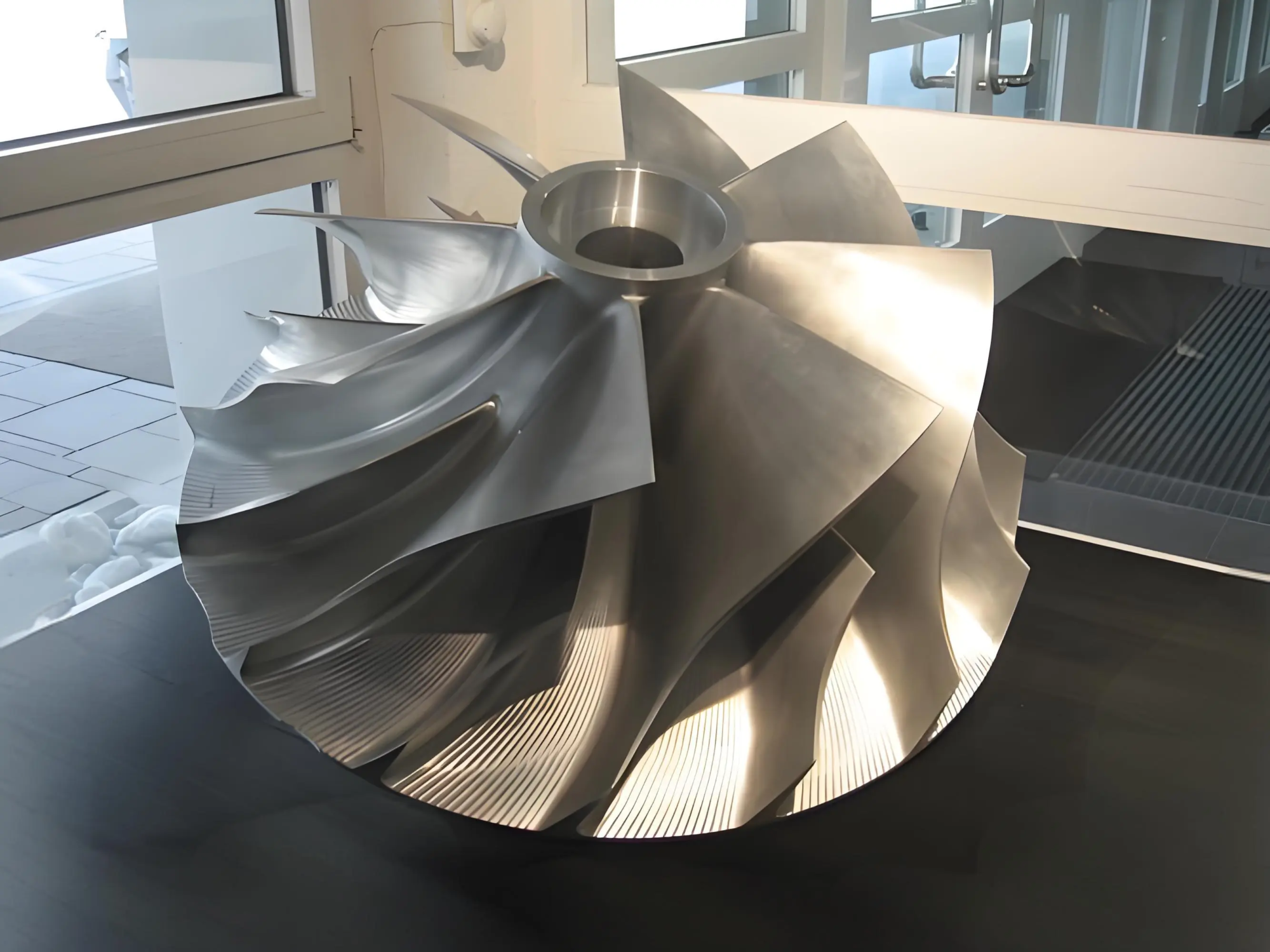

Precision CNC (Computer Numerical Control) machining is a high-accuracy manufacturing process that utilizes computer-controlled tools and machinery to produce parts with exceptional precision. The process involves programming machines to follow specific instructions, enabling the creation of complex geometries that are otherwise difficult or impossible to achieve using traditional manufacturing methods.

Key Characteristics of Precision CNC Machining

- Accuracy: Precision CNC machining ensures tight tolerances and consistent results, making it ideal for applications requiring high dimensional accuracy.

- Efficiency: Automated processes reduce manual intervention, enhancing production efficiency and minimizing errors.

- Versatility: CNC machines can handle a wide range of materials, including metals, plastics, and composites.

- Scalability: The technology supports both prototype development and mass production with consistent quality.

Types of CNC Machining Processes

Drilling: Produces accurate and consistent holes with minimal effort.

Milling: Involves rotating cutting tools to remove material from a workpiece. Capable of creating complex shapes and fine details.

Turning: Utilizes a lathe to rotate the workpiece while a cutting tool shapes it, ideal for cylindrical parts.

EDM (Electrical Discharge Machining): Uses electrical discharges to shape hard materials, suitable for intricate and delicate components.

Laser Cutting: Employs high-energy lasers for precise cutting and engraving tasks.

Applications of CNC Machined Parts

CNC machined parts are integral to numerous industries due to their precision and reliability. Here are some of the key application areas:

1. Aerospace Industry

- High-precision components for aircraft engines, landing gears, and structural parts.

- Lightweight and durable materials such as aluminum and titanium are commonly used.

- Stringent quality checks to ensure safety and reliability in harsh environments.

2. Automotive Industry

- Engine components, transmission systems, and custom parts.

- High-performance and durable materials ensure reliability and longevity.

- CNC machining contributes to the development of electric vehicle components and lightweight structures for fuel efficiency.

3. Medical Equipment

- Surgical instruments, implants, and diagnostic devices.

- Materials must meet strict biocompatibility and sterilization standards.

- CNC machining facilitates the production of custom prosthetics and orthopedic devices.

4. Electronics

- Precision housings and connectors for electronic devices.

- CNC machining provides excellent thermal and electrical properties.

- Enables miniaturization and complex geometries for modern electronics.

5. Industrial Machinery

- Gears, shafts, and custom machine components.

- High durability and wear resistance are critical.

- CNC machining supports heavy-duty machinery and equipment development.

6. Defense and Military

- Components for firearms, vehicles, and communication devices.

- CNC machining ensures high accuracy for mission-critical applications.

Features of CNC Machined Parts

1. High Precision

Precision CNC machining achieves tight tolerances, often within microns, making it suitable for applications demanding exact specifications.

2. Diversified Applications

CNC machined parts are widely used in various machinery, such as:

- Metal recycling machines

- Metal cutting machines

- Metal processing machinery

- Metal forging and engraving machinery

- Metal coating machinery

3. Customized Services

- Tailored solutions based on customer requirements.

- Flexibility to create unique designs for specialized applications.

- Options for secondary processes such as anodizing, plating, and painting to meet specific needs.

4. Mass Production Capabilities

- Efficiently supports large-scale production without compromising quality.

- Ideal for industries requiring high volumes of precision components.

- Automated systems ensure consistency across thousands of units.

5. Material Versatility

- Supports a wide range of materials, including aluminum, stainless steel, brass, titanium, and engineering plastics.

- Offers material certifications and traceability for critical industries.

Advantages of Great Light’s Precision CNC Machining

As a leading provider of precision CNC machining services, Great Light offers unparalleled advantages:

1. State-of-the-Art Equipment

- Advanced 5-axis CNC machines capable of producing complex geometries.

- High-speed and high-precision tools for superior results.

- Multi-tasking capabilities combining milling, turning, and drilling in a single operation.

2. Stringent Quality Control

- Comprehensive inspection processes ensure every part meets exact specifications.

- Utilization of cutting-edge metrology tools for precise measurements, including CMM (Coordinate Measuring Machines).

- Implementation of Statistical Process Control (SPC) to maintain consistency.

3. Premium Materials

- Access to a wide range of high-quality metals and plastics.

- Materials are sourced from trusted suppliers to guarantee consistency and durability.

- Expertise in selecting the best material for specific applications based on performance requirements.

4. Streamlined Production Process

- Efficient workflows reduce lead times while maintaining quality.

- Expertise in both prototype development and mass production.

- Integration of digital twin technology to simulate and optimize machining operations.

5. One-Stop Solution

- From initial design to final finishing, Great Light provides comprehensive services, including post-processing and surface treatments.

- Options for heat treatment, polishing, sandblasting, and other finishing techniques.

6. Sustainability Focus

- Adoption of energy-efficient machining practices.

- Recycling and waste management systems to minimize environmental impact.

Why Choose Great Light for CNC Machined Parts?

Great Light’s expertise in precision CNC machining ensures high-quality solutions tailored to your needs. Whether you’re looking for rapid prototyping or large-scale production, Great Light’s capabilities make it the go-to choice for industries worldwide.

- Rapid Turnaround: Quick processing and delivery of parts to meet tight deadlines.

- Competitive Pricing: Cost-effective solutions without compromising on quality.

- Customer-Centric Approach: Dedicated support and customization options to ensure satisfaction.

- Technological Expertise: Use of the latest machining technologies to address complex requirements.

Order your highly complex CNC machined parts today and experience unmatched precision and efficiency with Great Light!