High-Quality Milling with 5-Axis CNC Machining

Milling is one of the most versatile and widely used machining processes in manufacturing, and 5-axis CNC machining represents the pinnacle of technological advancement in this field. This guide provides an in-depth understanding of high-quality milling with 5-axis CNC machining, its advantages, best practices, and the role of Great Light as a leading supplier in the industry.

What is Milling with 5-Axis CNC Machining?

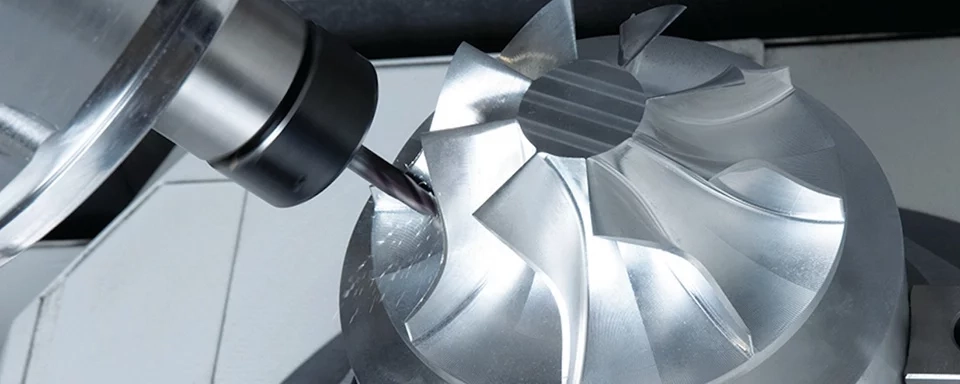

Milling with 5-axis CNC (Computer Numerical Control) machining refers to the process of using a milling machine that can move a cutting tool or workpiece in five different axes simultaneously. Unlike traditional 3-axis machining, which moves along three linear axes (X, Y, and Z), 5-axis CNC machining incorporates two additional rotational axes (A and B). This advanced movement capability enables complex geometries and intricate designs to be achieved with unparalleled precision.

Key Features of 5-Axis Milling:

- Simultaneous Movement: Ability to process intricate surfaces by coordinating all five axes.

- Complex Geometry Handling: Perfect for parts with undercuts, deep cavities, and angular features.

- High Precision: Achieves tight tolerances and smooth surface finishes.

Examples of products manufactured using this technology include aerospace components, medical devices, and intricate automotive parts.

Why Use 5-Axis CNC Machining for Milling?

The decision to use 5-axis CNC machining stems from the numerous advantages it offers over traditional milling techniques. Here are the primary reasons:

1. Enhanced Design Flexibility:

5-axis machining allows the creation of parts with complex geometries that would be impossible or highly inefficient with 3-axis machines.

2. Improved Accuracy and Precision:

By reducing the need for repositioning the workpiece, 5-axis machining minimizes human error and ensures consistent accuracy.

3. Increased Efficiency:

Fewer setups mean shorter production times. This efficiency not only reduces costs but also accelerates time-to-market.

4. Better Surface Finishes:

The ability to position the tool at optimal angles reduces tool wear and improves the surface quality of the finished product.

5. Versatility Across Materials:

5-axis CNC machines can handle a wide range of materials, including metals like aluminum, titanium, and stainless steel, as well as plastics and composites.

Precautions for High-Quality Milling with 5-Axis CNC Machining

Achieving high-quality results with 5-axis CNC machining requires attention to several critical factors. Here are some best practices:

1. Material Selection:

Choose materials compatible with 5-axis machining. Consider properties like hardness, machinability, and thermal conductivity.

2. Tooling:

Use high-quality, precise cutting tools designed for the specific material being processed. Regularly inspect and maintain tooling to ensure optimal performance.

3. Programming Accuracy:

Invest in advanced CAD/CAM software to create precise toolpaths. Accurate programming is essential for complex geometries.

4. Machine Calibration:

Regular calibration ensures the machine maintains accuracy over time. Address wear and tear promptly to prevent deviations.

5. Operator Training:

Skilled operators familiar with 5-axis machining processes and software are critical for maximizing the machine’s capabilities.

6. Workholding and Fixturing:

Secure and precise workholding prevents movement during machining, ensuring consistent results.

Advantages of High-Quality Milling with 5-Axis CNC Machining

1. Reduced Setup Time:

One of the significant advantages is the ability to machine parts in a single setup, eliminating the need for multiple repositioning steps.

2. Improved Productivity:

With reduced manual intervention and faster cutting speeds, 5-axis machines significantly boost production efficiency.

3. Cost-Effectiveness:

Although the initial investment in 5-axis machining is high, the long-term benefits in terms of time savings and quality make it a cost-effective solution.

4. Customizability:

Manufacturers can easily customize designs to meet specific client requirements, thanks to the machine’s versatility.

5. Future-Proof Technology:

As industries evolve, the demand for complex and precise parts is increasing. 5-axis machining aligns perfectly with these trends.

Benefits of High-Quality Milling with 5-Axis CNC Machining

1. Industry Applications:

5-axis CNC machining is indispensable in industries like:

- Aerospace: For components like turbine blades and structural parts.

- Medical: For surgical instruments and prosthetics.

- Automotive: For precision engine and transmission parts.

- Energy: For manufacturing turbines and other energy-generation components.

2. Enhanced Product Quality:

The precision of 5-axis machines ensures that the final product meets stringent quality standards.

3. Scalability:

From prototyping to large-scale production, 5-axis machining adapts seamlessly to varying production demands.

4. Sustainability:

Efficient use of materials and energy contributes to eco-friendly manufacturing processes.

Great Light: Your Trusted Partner in 5-Axis CNC Machining

As a professional supplier of high-quality milling with 5-axis CNC machining, Great Light stands out for its expertise and advanced capabilities. Here’s why clients choose us:

1. Advanced Equipment:

We utilize state-of-the-art 5-axis CNC machines for unparalleled precision and efficiency.

2. Comprehensive Services:

From design to production and post-processing, we provide end-to-end solutions tailored to your needs.

3. Material Versatility:

Great Light can process a wide range of materials, ensuring we meet diverse industry requirements.

4. Expertise:

Our team of experienced professionals ensures the highest quality standards in every project.

5. Competitive Pricing:

We offer cost-effective solutions without compromising on quality, making us the ideal partner for your custom milling needs.

Conclusion

High-quality milling with 5-axis CNC machining is a game-changer in modern manufacturing. Its ability to handle complex designs, deliver precision, and improve efficiency makes it an invaluable tool across industries. Great Light’s advanced technology and expertise ensure that your projects benefit from the full potential of this cutting-edge process.

Ready to elevate your manufacturing capabilities? Contact Great Light today to customize your high-quality milling solutions at the best price!