CNC Machining Services UK: A Comprehensive Guide to the Current Landscape and Online Ordering Benefits

Introduction

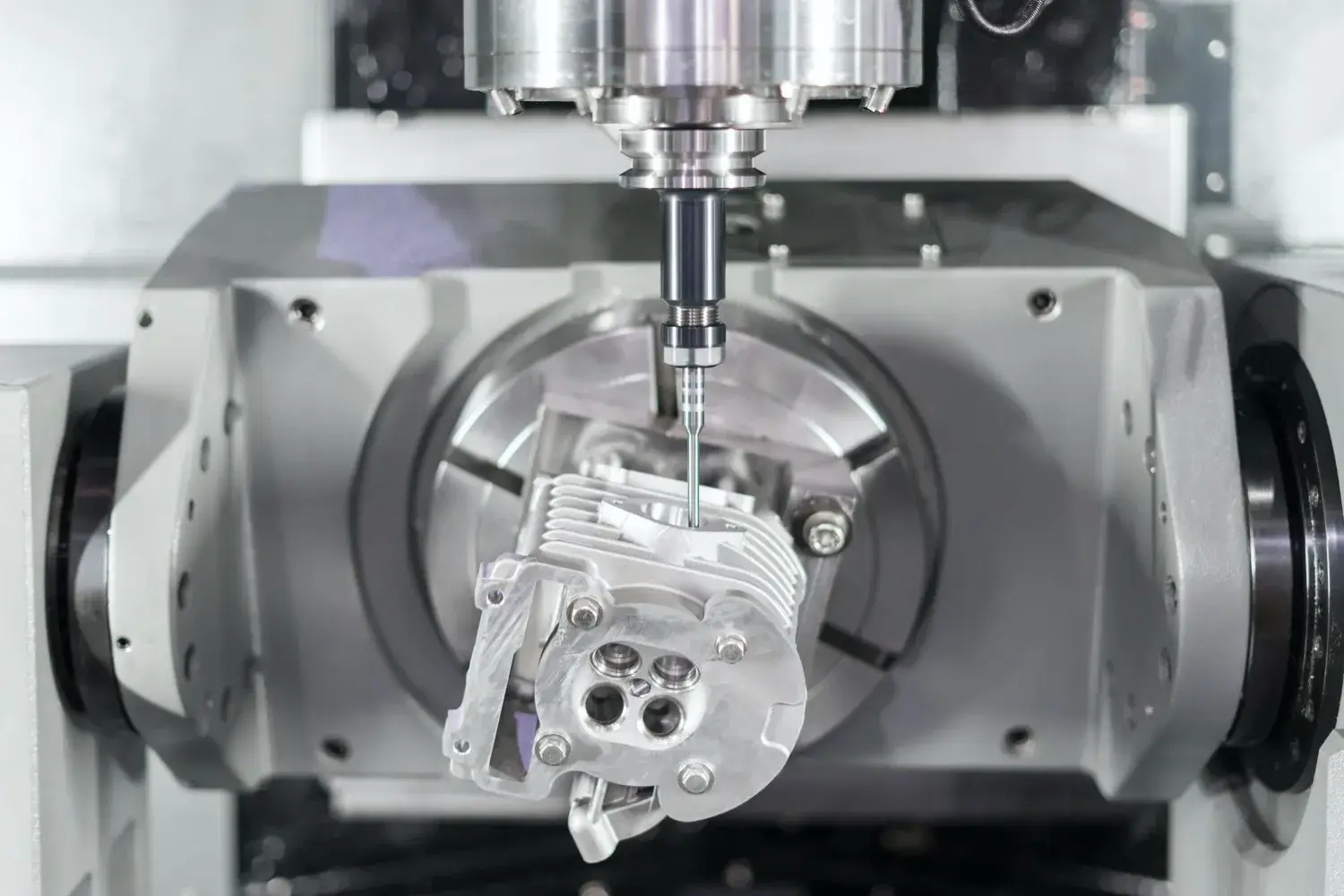

The global manufacturing industry has seen a rapid shift toward automation, and the UK’s CNC machining services are no exception. CNC (Computer Numerical Control) machining is now a standard in modern manufacturing due to its precision, efficiency, and versatility. In the UK, the demand for CNC machining services has surged as industries ranging from aerospace to automotive to healthcare require high-quality, reliable, and cost-effective solutions. In this article, we will explore the current state of CNC machining services in the UK, provide an analysis of leading companies, compare traditional services with online CNC machining services, and delve into the advantages of online ordering.

The Current Landscape of CNC Machining Services in the UK

The UK has long been known for its innovative engineering and manufacturing sectors. As CNC machining has become a central technology in manufacturing processes, it has transformed the way businesses approach production. In recent years, several factors have contributed to the rise of CNC machining services in the UK, including:

- Demand for Precision: As industries become more technologically advanced, the need for highly precise and repeatable machining processes has grown. CNC machines are capable of producing parts with a level of precision that traditional machining methods could never achieve, making them indispensable in fields such as aerospace, automotive, medical device manufacturing, and electronics.

- Rapid Technological Advancements: CNC machines have evolved dramatically in terms of both their hardware and software. The introduction of multi-axis machines, improved software for design and simulation, and more automated processes have enhanced the capabilities of CNC machining services in the UK.

- Diversification of Applications: From custom one-off prototypes to mass production runs, CNC machining in the UK is now applied in a wide variety of sectors. This has allowed service providers to specialize in particular industries and offer tailored solutions, further driving the expansion of CNC machining services.

- Brexit and Supply Chain Challenges: Post-Brexit, many UK manufacturers have faced challenges related to supply chains and logistics. However, the demand for local suppliers providing high-quality and quick-turnaround CNC machining services has increased, which in turn has benefitted local CNC machining companies.

- Increased Focus on Sustainability: With a growing global focus on environmental impact, many UK CNC machining companies are adopting more sustainable practices. These include using recyclable materials, reducing waste through more efficient machining, and utilizing energy-efficient machines.

Top CNC Machining Services UK Companies: Analysis and Comparison

To better understand the landscape, it’s helpful to analyze some of the leading CNC machining services providers in the UK. Below is a table summarizing 10 representative CNC machining companies in the UK. We’ll examine their company size, advantages, disadvantages, and directions for improvement.

| Company Name | Company Size | Advantages | Disadvantages | Directions for Improvement |

|---|---|---|---|---|

| XYZ Precision | Medium to Large | High precision, experienced in aerospace | Limited rapid prototyping capabilities | Focus on expanding rapid prototyping options |

| ABC Machining | Small to Medium | Low cost, fast turnaround, flexible service | Limited range of materials | Expand material options, invest in automation |

| Metallus CNC | Large | State-of-the-art equipment, quick setup | High costs for small batches | Offer more cost-effective solutions for small batches |

| Techno CNC | Medium | Specialize in custom orders, advanced 5-axis machining | Lead time can be long during peak seasons | Improve lead times by increasing production capacity |

| Precision Parts | Small | Focus on small batches and prototypes | Limited scalability | Develop capabilities for larger batch orders |

| Elite Machining | Large | Advanced CAD/CAM integration, great for complex designs | Expensive for smaller businesses | Offer tiered pricing based on order volume |

| Future CNC | Small | Excellent customer support, wide range of materials | Limited multi-axis capabilities | Invest in advanced multi-axis machines |

| Swift CNC Services | Medium | Fast turnaround, specializes in precision parts | Limited high-volume capacity | Expand capacity for high-volume orders |

| Aero CNC | Large | Extensive experience in aerospace industry | High setup costs for small jobs | Offer more competitive pricing for small production runs |

| Northern CNC | Small to Medium | Focus on high-precision work, good for medical sectors | Expensive for low-volume orders | Focus on reducing costs for smaller businesses |

Key Insights from the Analysis:

- Specialization and Experience: Many of the top CNC machining services in the UK have specific industries they specialize in, such as aerospace, medical, or automotive sectors. This specialization helps them build a reputation for delivering high-quality, precision-engineered parts.

- Cost Efficiency vs. Precision: Smaller companies often focus on providing cost-effective solutions, while larger companies may prioritize high precision, particularly for industries like aerospace.

- Expansion of Capabilities: Some CNC machining companies, especially those serving smaller businesses, could benefit from expanding their capabilities to include rapid prototyping, multi-axis machining, and higher-volume production.

The Rise of Online CNC Machining Services: Advantages and Benefits

As the world continues to embrace digital transformation, CNC machining services in the UK are following suit by offering online ordering platforms. The shift toward online CNC machining services brings with it a number of distinct advantages, making it easier for customers to access services and get quotes.

1. Convenience and Accessibility

Online CNC machining services allow customers to place orders at any time, from anywhere. This eliminates the need for phone calls or face-to-face meetings and gives businesses the flexibility to handle urgent orders without the delays typically associated with traditional methods.

2. Faster Turnaround Times

With online CNC machining, the process from quoting to ordering is streamlined. Customers can upload their CAD designs, receive instant quotes, and place orders without waiting for lengthy consultations or back-and-forth communication.

3. Transparent Pricing

Many online CNC machining services in the UK provide transparent pricing models. Customers can upload their designs and get an instant quote, helping them better manage their budgets and understand the cost breakdown. This also reduces the likelihood of unexpected price changes once the project is underway.

4. Real-time Tracking

Online CNC machining services typically offer real-time tracking for orders. Customers can see the status of their orders and production schedules, providing greater visibility into the process and enhancing customer satisfaction.

5. Scalable Services for All Sizes of Orders

Whether a company requires a small batch for prototyping or a large run for mass production, online CNC machining services can accommodate orders of varying sizes. The flexibility of online platforms allows businesses to easily scale up or down depending on their needs.

6. Advanced Features and Tools

Many online CNC machining platforms come equipped with CAD software and simulation tools, enabling customers to upload their designs, visualize the final product, and even make real-time adjustments to their orders. This reduces errors and helps ensure a more accurate finished product.

7. Cost Savings

Online CNC machining services can often provide more competitive pricing due to lower overhead costs. Without the need for a physical storefront or heavy administrative staff, these services can pass the savings onto customers. Additionally, automated processes and digital workflows reduce human errors and inefficiencies, leading to cost reductions.

8. Reduced Lead Times

With automated ordering, online platforms can reduce lead times by bypassing the traditional manual quoting process. Orders are processed faster, and manufacturers can begin production sooner, resulting in quicker delivery of parts.

How Great Light’s CNC Machining Services UK Stand Out

Great Light is one of the key players in the UK’s CNC machining market, offering both traditional and innovative CNC machining services. Specializing in small, medium, and large batch CNC machining, Great Light stands out in the following ways:

- Rapid Turnaround: Great Light excels in delivering quick turnaround times for a range of industries, from medical to automotive. Their use of advanced technologies and efficient workflows allows them to process most metal materials quickly.

- One-Stop Post-Finishing Services: Beyond machining, Great Light also offers post-finishing services such as anodizing, powder coating, and assembly. This allows clients to receive fully finished products ready for immediate use.

- Flexible Order Quantities: Whether you’re looking for a single prototype or large-scale production runs, Great Light can handle orders of any size. Their scalable operations ensure that both small businesses and large enterprises receive the same high level of service.

- Online Ordering for Maximum Convenience: Great Light offers an easy-to-use online ordering platform that simplifies the process of ordering CNC machined parts. Customers can upload their CAD designs, receive instant quotes, and place orders with just a few clicks.

- Material Expertise: With experience working with a wide variety of materials, including metals and plastics, Great Light is equipped to handle a broad range of CNC machining applications.

Directions for Improvement in CNC Machining Services UK

Despite the rapid growth of CNC machining services in the UK, there is still room for improvement in certain areas:

- Expanding Technological Capabilities: Investing in advanced machinery, such as multi-axis CNC machines, could help UK CNC machining companies stay competitive on the global stage.

- Sustainability Efforts: There is increasing pressure from both consumers and governments to reduce carbon footprints. CNC machining companies can improve sustainability by adopting more eco-friendly materials, energy-efficient machines, and waste reduction practices.

- Supply Chain Resilience: Post-Brexit, UK manufacturers need to strengthen supply chain strategies to avoid disruptions. Building closer relationships with suppliers and diversifying material sources can help mitigate future challenges.

- Better Integration with Industry 4.0: As the UK manufacturing sector continues to embrace Industry 4.0, CNC machining services need to integrate IoT, AI, and machine learning to optimize operations and increase efficiency.

Conclusion

The CNC Machining Services UK continues to evolve, driven by advances in technology, increased demand for precision manufacturing, and the convenience of online ordering. Companies like Great Light are at the forefront of this transformation, offering high-quality services for businesses of all sizes. With the right technological advancements, customer service focus, and continuous improvement, the future of CNC machining services in the UK looks brighter than ever.