The Ultimate Guide to 5 Axis CNC Machines and CNC Machining Near Me

CNC machining is revolutionizing manufacturing across industries. Among its many advancements, the 5 Axis CNC Machine stands out as a pinnacle of precision engineering. Combined with the growing demand for localized services such as CNC machining near me, the landscape of custom machining has changed dramatically. In this comprehensive guide, we delve into the types, brands, and applications of 5 Axis CNC Machines, the benefits of localized CNC services, and how online CNC customization can optimize your manufacturing needs.

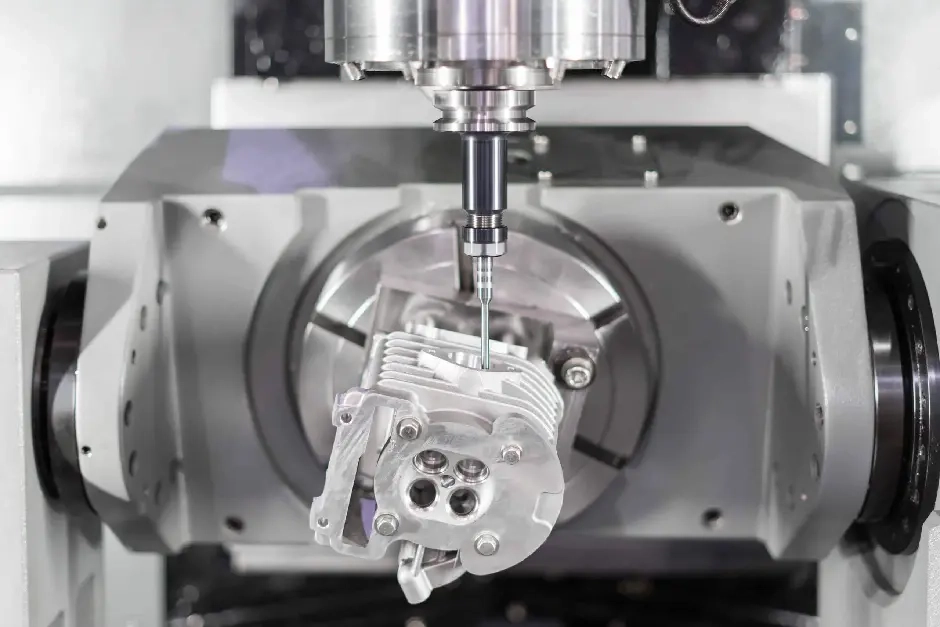

What is a 5 Axis CNC Machine?

A 5 Axis CNC Machine is a computer-controlled manufacturing tool capable of moving a cutting tool or workpiece along five axes simultaneously. Unlike traditional 3-axis machines, these advanced systems add two rotational axes to increase flexibility and precision, making them ideal for complex geometries.

Types of 5 Axis CNC Machines

- Swivel Head Machines:

- The cutting tool moves along the additional axes.

- Advantages: Compact setup, ideal for small workspaces.

- Applications: Aerospace and automotive components.

- Table/Table Machines:

- The workpiece rotates and tilts.

- Advantages: High stability for larger parts.

- Applications: Large-scale molds and architectural components.

- Swivel Table/Fixed Spindle Machines:

- Combines features of swivel head and table/table types.

- Advantages: Greater versatility for medium to large parts.

- Applications: Medical implants and industrial tooling.

Common Brands and Models of 5 Axis CNC Machines

Several brands dominate the 5 Axis CNC market, each offering unique features and benefits:

1. HAAS Automation

- Popular Models: UMC-750, VF-6/40TR

- Advantages: Cost-effective solutions with user-friendly controls.

- Applications: General-purpose manufacturing and prototyping.

2. DMG Mori

- Popular Models: DMU 50, DMU eVo series

- Advantages: High precision, robust build quality.

- Applications: Aerospace, automotive, and luxury goods.

3. Mazak

- Popular Models: Variaxis i-300, Variaxis C-600

- Advantages: Advanced multi-tasking capabilities.

- Applications: High-complexity parts and batch production.

4. Okuma

- Popular Models: MU-4000V, MU-8000V

- Advantages: Reliability and innovative thermal control.

- Applications: Tooling and heavy-duty industries.

What Can 5 Axis CNC Machines Process?

Material Compatibility

- Metals: Aluminum, stainless steel, titanium, copper, and brass.

- Plastics: ABS, PEEK, polycarbonate, and nylon.

- Others: Composites, ceramics, and wood.

Workpiece Size

5 Axis CNC Machines handle a range of part sizes:

- Small-scale parts: Precision implants or watch components.

- Large-scale components: Aerospace fuselage or large molds.

Machines vary in capacity, with typical sizes ranging from small desktop units to industrial-scale setups.

Choosing the Right 5 Axis CNC Machine for Your Needs

Key Considerations

- Workpiece Complexity:

Choose swivel head machines for intricate designs. - Material Type:

Ensure the machine’s spindle power matches material hardness. - Production Volume:

For large batches, prioritize stability and automated features. - Budget:

HAAS offers cost-efficient models; DMG Mori caters to high-end requirements.

CNC Machining Near Me: Advantages and Disadvantages

Advantages

- Fast Turnaround: Localized facilities reduce shipping times.

- Support and Communication: Easier access to on-site experts for troubleshooting.

- Customization: Tailored solutions based on your unique needs.

Disadvantages

- Cost: Local services may charge a premium compared to international vendors.

- Limited Scalability: Smaller workshops might struggle with high-volume production.

Online Custom CNC Machining: Benefits in Practical Applications

Why Choose Online CNC Services?

- Efficiency: Receive instant quotes by uploading your CAD files.

- Global Access: Tap into a network of suppliers regardless of location.

- Scalability: Handle both small prototypes and large-scale production seamlessly.

Key Features

- End-use parts delivered in as little as three days.

- Access to over 100 CNC machines and 40+ materials.

- High precision for industries like medical, aerospace, and consumer electronics.

5 Axis CNC Machine External Processing Services

High-precision external CNC machining services using 5 Axis CNC Machines offer unparalleled flexibility. At Great Light, we specialize in:

- CNC Turning: For cylindrical components.

- CNC Milling: For flat surfaces and complex geometries.

- 5 Axis Machining: For intricate, multi-sided parts.

With advanced equipment and streamlined processes, we guarantee:

- Rapid prototyping for design validation.

- Small to large batch manufacturing.

- Competitive pricing without compromising quality.

Great Light: Your Partner for CNC Machining

At Great Light, we excel in:

- On-demand manufacturing: From single prototypes to large-scale production.

- Material versatility: Metals and plastics alike can be machined to precise tolerances.

- Customization: Every order is tailored to meet your specifications.

Conclusion

The 5 Axis CNC Machine has redefined modern manufacturing, providing unmatched accuracy and efficiency for complex designs. Whether you’re searching for CNC machining near me or considering online customization, understanding your needs is the first step. With Great Light’s advanced machinery and expert services, we ensure your manufacturing goals are achieved with precision and reliability.

Order your CNC parts now and experience the future of high-quality, on-demand machining!