Understanding 5-Axis CNC Machines: Precision and Versatility in Modern Manufacturing

In the realm of precision manufacturing, 5-axis CNC (Computer Numerical Control) machines have revolutionized the production of complex components. Unlike traditional 3-axis machines, which operate along the X, Y, and Z linear axes, 5-axis machines incorporate two additional rotational axes—commonly referred to as the A and B axes. This configuration enables the cutting tool to move simultaneously along five axes, allowing for intricate and precise machining of parts with complex geometries.

What Is A 5 Axis CNC Machine?

To help understand what a 5-axis machine is, let’s first explain axis count in CNC machining.

The number of machining axes describes the number of directions a CNC cutting tool (or workpiece) can move to produce the desired machined part. For example, traditional CNC machines typically have a three-axis count, meaning their cutting tools can move across the X, Y, and Z axes—laterally in the X axis, vertically in the Y axis, and forward and backward in the Z axis (see Figure 1).

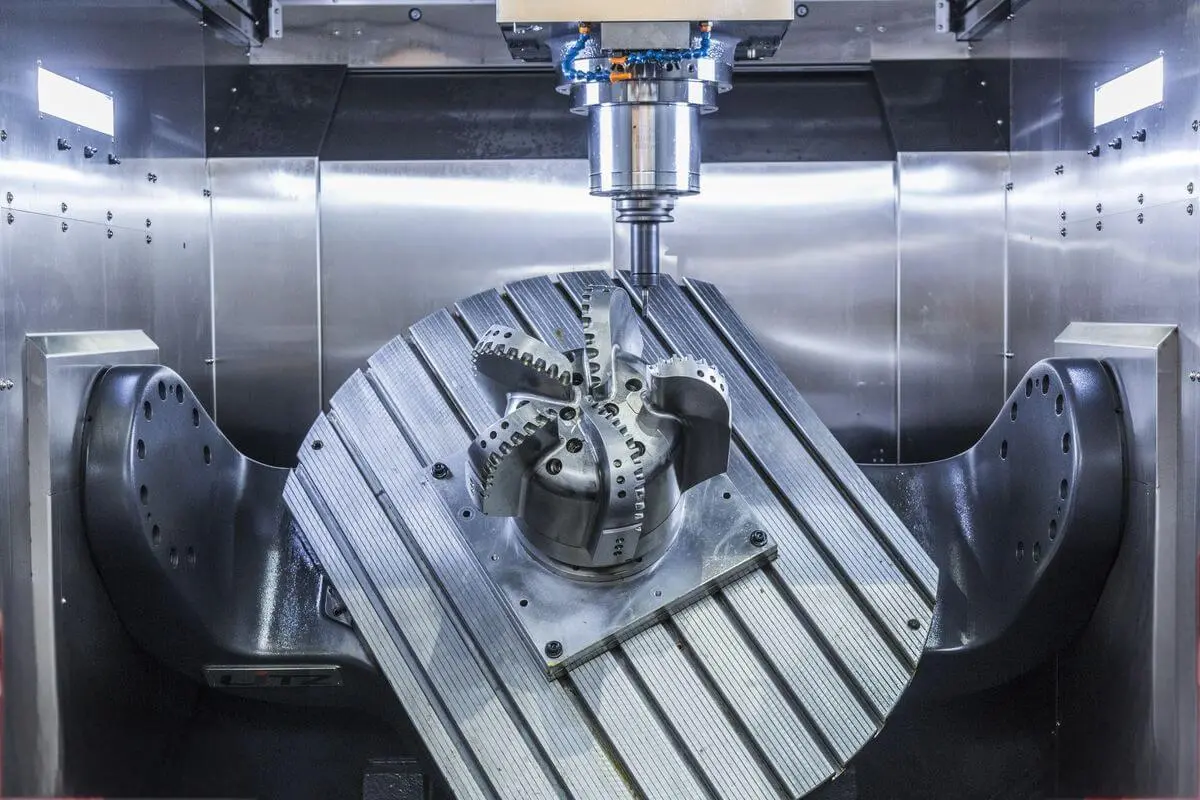

In addition to these three linear axes, 5-axis CNC machines have the ability to tilt (and rotate) the table that holds the workpiece, as shown in Figure 1. These two new rotary axes are often called the A-axis (or tilt table axis) and the C-axis (or table rotation axis); they allow you to machine more complex geometries than a 3-axis CNC machine.

How Do 5-Axis CNC Machines Work?

The operation of a 5-axis CNC machine involves the coordinated movement of the cutting tool and the workpiece across five axes:

- X-Axis: Movement from left to right.

- Y-Axis: Movement from front to back.

- Z-Axis: Movement from top to bottom.

- A-Axis: Rotation around the X-axis.

- B-Axis: Rotation around the Y-axis.

This multi-axis movement allows for the machining of complex parts in a single setup, reducing the need for multiple fixtures and setups.

Advantages of 5-Axis CNC Machining

- Enhanced Precision and Accuracy: The simultaneous movement along five axes allows for the creation of intricate parts with high precision, meeting the stringent tolerances required in industries such as aerospace, medical devices, and automotive manufacturing.

- Reduced Setup Time: By machining multiple sides of a part in a single setup, 5-axis CNC machines minimize the need for repositioning, thereby reducing setup times and increasing overall production efficiency.

- Improved Surface Finish: The ability to approach the workpiece from various angles enables the use of optimal cutting paths, resulting in superior surface finishes and reduced post-processing requirements.

- Increased Tool Life: The dynamic movement capabilities allow for optimal tool engagement, which can lead to extended tool life and reduced tool wear.

- Capability to Machine Complex Geometries: 5-axis CNC machines are adept at producing parts with complex shapes, including undercuts and intricate contours, which are challenging or impossible to achieve with traditional 3-axis machines.

Applications of 5-Axis CNC Machining

The versatility of 5-axis CNC machines makes them ideal for a wide range of applications, including:

- Aerospace Components: Manufacturing parts such as turbine blades, engine components, and structural elements that require high precision and complex geometries.

- Medical Devices: Producing intricate surgical instruments, implants, and prosthetics that demand tight tolerances and biocompatible materials.

- Automotive Parts: Creating complex engine components, transmission parts, and custom tooling that require both precision and durability.

- Mold and Die Making: Fabricating molds and dies for injection molding, casting, and stamping processes, which often involve complex shapes and high precision.

Great Light’s Expertise in 5-Axis CNC Machining

As a leading 5-axis CNC machining manufacturer, Great Light leverages advanced equipment and production technology to address complex metal parts manufacturing challenges. We offer comprehensive post-processing and finishing services, ensuring that most materials can be quickly customized and processed to meet specific requirements. Our 5-axis CNC machining services are particularly well-suited for customized precision titanium machining, providing high-quality parts at competitive prices.

The world’s top 20 five-axis CNC machine tools

5-axis CNC machines are essential for producing complex parts with high precision across various industries, including aerospace, automotive, and medical sectors. Below is a table summarizing some of the top 5-axis CNC machines, highlighting their brand names, main models, processing dimensions, market prices, advantages, and disadvantages. Please note that prices are approximate and can vary based on configurations and additional features.

| Brand Name | Main Model | Processing Dimensions (mm) | Market Price (USD) | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Okuma | MU-6300V | 1,200 x 1,000 x 1,000 | $500,000 – $600,000 | Advanced control systems, durability, and versatility. High spindle speed and superior thermal stability. | Higher price point. Complex maintenance requirements. |

| DMG Mori | DMU 65 monoBLOCK | 650 x 650 x 650 | $400,000 – $500,000 | Cutting-edge technology, precision, and global support. High dynamic response, accuracy of 0.001 mm. | Complex maintenance requirements. |

| Makino | a51nx | 510 x 460 x 460 | $350,000 – $450,000 | Exceptional speed and precision for die/mold machining. High RPM spindles, advanced cooling systems. | Expensive initial investment. |

| Mazak | VARIAXIS i-700 | 700 x 600 x 500 | $300,000 – $400,000 | Innovative multi-tasking machines, user-friendly. Smooth control technology, high torque spindles. | Limited customization options. |

| Haas Automation | UMC-750 | 762 x 508 x 508 | $150,000 – $200,000 | Affordable, robust, and easy-to-use machines. Simple programming, moderate precision. | Less suited for ultra-precision. |

| Doosan | DNM 5700 | 600 x 570 x 500 | $200,000 – $300,000 | Cost-effective and versatile machines. Sturdy construction, good torque. | Limited high-end features. |

| FANUC | ROBODRILL α-D21MiB5 | 500 x 400 x 330 | $250,000 – $350,000 | Leading CNC control technology, reliable machines. State-of-the-art CNC controls, energy-efficient. | Limited hardware diversity. |

| Hardinge | Bridgeport XT Series | 762 x 508 x 508 | $200,000 – $300,000 | Specializes in high-precision turning and milling. Outstanding surface finish capabilities. | Smaller production capacity. |

| EMAG | VSC 400 | 400 x 400 x 400 | $300,000 – $400,000 | Advanced modular design and automation solutions. High productivity, automation-ready. | Niche focus on vertical machines. |

| TRUMPF | TruMatic 6000 | 1,500 x 1,500 x 200 | $500,000 – $600,000 | Leader in laser cutting and innovative solutions. Superior cutting speed, excellent edge quality. | High cost for premium models. |

| Hurco | VMX30Ui | 762 x 508 x 508 | $200,000 – $300,000 | User-friendly controls, efficient for small batches. Simple interface, moderate flexibility. | Limited support outside the USA. |

| Maslow CNC | Maslow CNC Kit | 1,000 x 1,000 x 100 | $500 – $1,000 | Affordable DIY CNC kits. Entry-level specifications for hobbyists. | Lower precision and performance. |

| Bantam Tools | Desktop CNC Milling Machine | 200 x 200 x 50 | $2,500 – $3,500 | Compact and beginner-friendly. Suitable for small prototypes and teaching. | Limited for industrial applications. |

| Spinner | U5-400 | 400 x 400 x 400 | $250,000 – $350,000 | Compact, precise machines ideal for small-scale shops. High accuracy for intricate parts. | Limited scalability. |

| Chiron | FZ 12 S | 1,200 x 1,000 x 1,000 | $400,000 – $500,000 | Exceptional for high-speed production environments. High-speed spindles, modular design. | Expensive maintenance. |

| Fidia | K Series | 1,200 x 1,000 x 1,000 | $500,000 – $600,000 | High-end milling machines for complex geometries. Excellent surface quality for die/mold parts. | Focus on niche industries. |

| GF Machining Solutions | Mikron MILL P 800 U | 800 x 800 x 600 | $400,000 – $500,000 | Precision EDM and milling machines. Micron-level accuracy, advanced automation. | High cost of ownership. |

Advantages of 5-Axis CNC Machines:

- Enhanced Precision: Offers high-accuracy machining for complex parts.

- Complex Geometry: Handles intricate designs and undercuts with ease.

- Reduced Setup Time: Fewer repositioning steps result in quicker operations.

- Wide Range of Applications: Suitable for aerospace, automotive, medical devices, and more.

Disadvantages of 5-Axis CNC Machines:

- High Initial Cost: The cost of purchasing a 5-axis machine tool and the software required are much higher than the cost of an ordinary three-axis machining center.

- Complex Programming: Programming is more difficult due to the complex spatial trajectory of the composite motion.

- High Technical Requirements for Operators: Advanced technology requires the operation of higher-level talents, leading to higher labor costs.

When selecting a 5-axis CNC machine, consider factors such as the complexity of the parts to be machined, production volume, available space, and budget constraints. Consulting with manufacturers and reviewing detailed specifications can help determine the most suitable machine for your specific needs.

Conclusion

What Is A 5 Axis CNC Machine?5-axis CNC machines represent a significant advancement in machining technology, offering unparalleled precision, efficiency, and versatility. Their ability to handle complex geometries with high accuracy makes them indispensable in modern manufacturing across various industries. Partnering with experienced CNC machining service providers like Great Light can ensure the successful realization of intricate designs and high-quality components.