Introduction: What is CNC Lathe Machining?

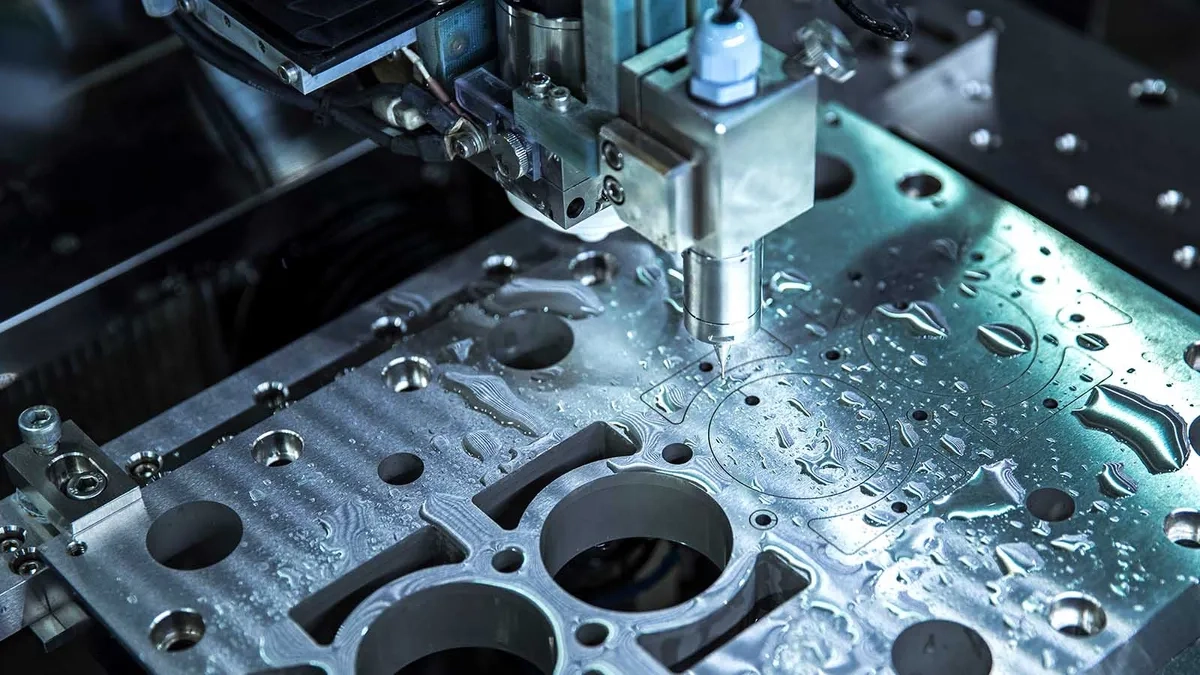

CNC (Computer Numerical Control) Lathe Machining is a highly precise and automated manufacturing process used to produce cylindrical parts and complex geometries. By utilizing programmed instructions, CNC lathes can cut, shape, and drill materials such as metals, plastics, and composites with exceptional accuracy.

Main Purpose of CNC Lathe Machining

The primary purpose of CNC Lathe Machining is to create high-quality, repeatable parts in a cost-effective and efficient manner. Its ability to handle intricate designs and meet tight tolerances makes it indispensable in industries like aerospace, automotive, medical, and consumer electronics.

Why is CNC Lathe Machining Popular Now?

1. High Precision and Consistency

Modern industries demand precision and repeatability, which CNC machining delivers flawlessly.

2. Automation and Efficiency

Automation reduces manual intervention, leading to faster production cycles and lower labor costs.

3. Versatility

CNC lathes can work with a wide range of materials and produce everything from prototypes to large-scale production runs.

4. Technological Advancements

Integration with CAD/CAM software, IoT, and AI has made CNC machining more efficient, accessible, and intelligent.

5. Sustainability

Minimized material wastage and energy-efficient designs align with global sustainability goals.

Popular CNC Lathe Machining Brands: Advantages and Disadvantages

| Brand | Advantages | Disadvantages |

|---|---|---|

| Haas Automation | Affordable, easy-to-use interface, reliable for most applications. | Limited customization options for niche applications. |

| Mazak | Advanced technology, multi-tasking capabilities, and high-quality builds. | Higher cost and steeper learning curve for beginners. |

| DMG MORI | Premium machines with cutting-edge features and precision. | Expensive, making it less accessible for small businesses. |

| Okuma | Robust and durable machines, excellent for heavy-duty applications. | High initial investment and maintenance costs. |

| Tormach | Budget-friendly, designed for small shops and hobbyists. | Limited capacity and features compared to industrial-grade machines. |

How to Use CNC Lathe Machining CNC Parts: A Step-by-Step Guide

Step 1: Understand the Basics of CNC Lathe Machining

- Familiarize yourself with the machine’s components, including the spindle, chuck, tool turret, and control panel.

- Learn how CNC programming works, focusing on G-code and M-code commands.

Step 2: Prepare the Design File

- Use CAD software to create a 3D model of the part you want to manufacture.

- Convert the design into machine-readable code using CAM software.

Step 3: Set Up the Machine

- Secure the workpiece using the chuck or collet.

- Load the appropriate cutting tools into the turret.

- Calibrate the machine by setting the zero point and adjusting tool offsets.

Step 4: Input the Program

- Upload the G-code file to the CNC lathe’s control system.

- Verify the program using simulation features to avoid errors.

Step 5: Perform a Test Run

- Conduct a dry run without cutting material to ensure the machine follows the correct path.

Step 6: Start the Machining Process

- Activate the machine to begin the cutting process.

- Monitor the operation for any irregularities, such as tool wear or material misalignment.

Step 7: Post-Processing

- Inspect the finished part for quality and precision using tools like calipers or CMMs (Coordinate Measuring Machines).

- Perform additional finishing processes, such as polishing or coating, if required.

Advantages of Great Light’s CNC Machining Services

1. Advanced Technology

Great Light utilizes state-of-the-art CNC lathe systems to deliver unmatched precision and speed.

2. Material Versatility

Capable of processing a wide range of metals and plastics, including titanium, stainless steel, aluminum, and engineering-grade polymers.

3. Comprehensive Solutions

Offering one-stop post-processing services like heat treatment, anodizing, and surface finishing.

4. Cost-Effective Options

Competitive pricing for both low-volume and high-volume production runs.

5. Customization and Support

Dedicated engineering teams work closely with clients to ensure every project meets their specifications.

Why Choose Great Light for CNC Machining Services?

Expertise in Complex Geometries

Great Light specializes in machining highly intricate parts that other providers might struggle to manufacture.

On-Time Delivery

Streamlined operations and robust logistics ensure timely delivery of every order.

Quality Assurance

Every part undergoes rigorous quality checks to guarantee it meets the highest industry standards.

Customer-Focused Approach

Great Light offers manual and instant quotation systems, enabling clients to choose the option that best suits their needs.

Future of CNC Lathe Machining

The future of CNC machining is shaped by emerging technologies and industry trends:

- Integration with IoT: Real-time monitoring and predictive maintenance through smart sensors.

- AI and Machine Learning: Optimizing machining parameters for efficiency and accuracy.

- Additive-Subtractive Manufacturing: Combining CNC machining with 3D printing for hybrid solutions.

- Eco-Friendly Practices: Using sustainable materials and energy-efficient processes.

Conclusion

CNC Lathe Machining is an indispensable technology for creating precise, high-quality parts across various industries. By leveraging advanced tools and techniques, Great Light ensures unparalleled service and results. Whether you’re producing prototypes or scaling up to mass production, Great Light’s CNC machining solutions deliver efficiency, precision, and reliability.

Order your custom CNC parts today and experience the Great Light difference!