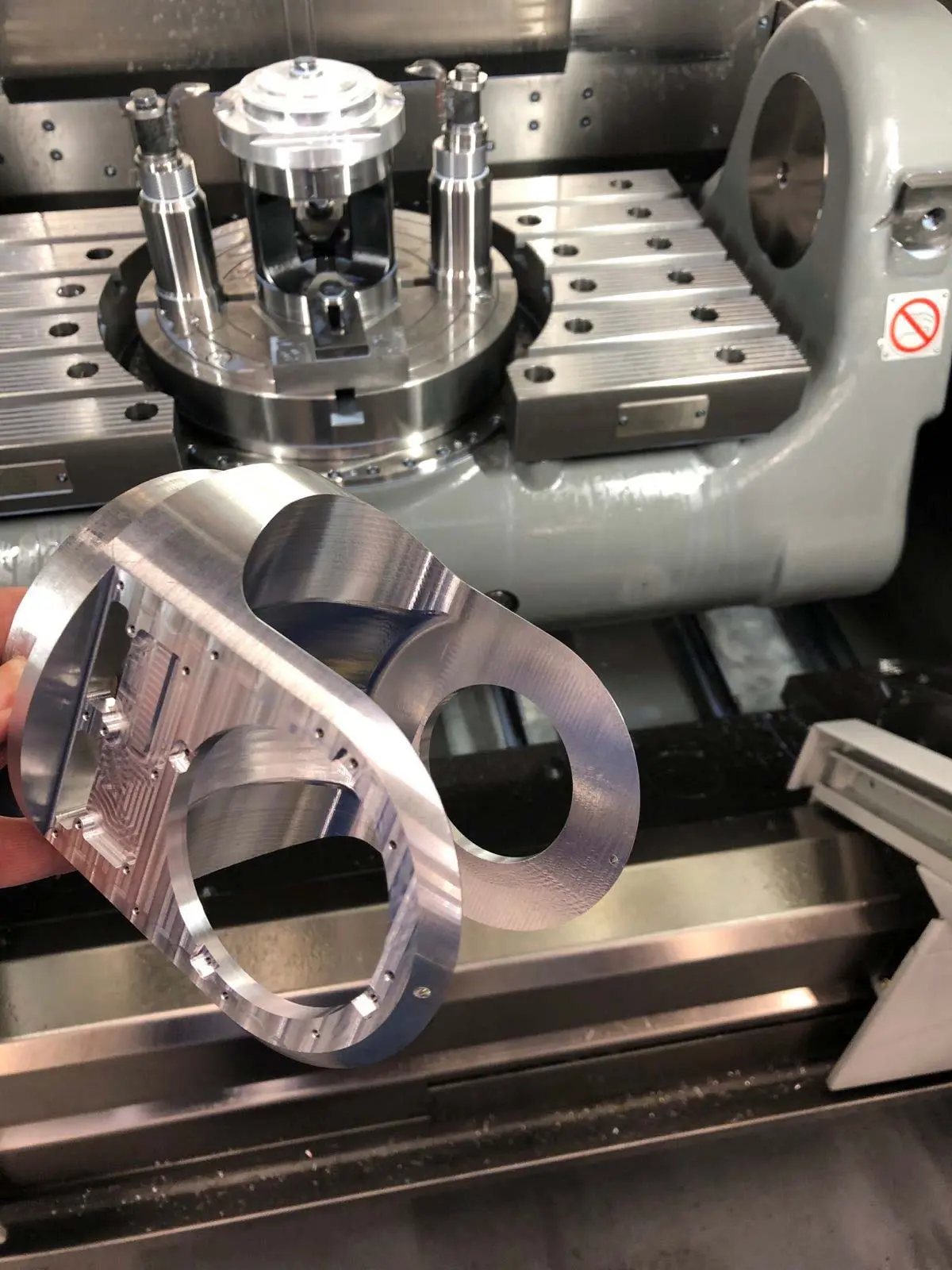

Custom Industrial Components Using 5-Axis CNC Machining

What are Custom Industrial Components?

Custom industrial components are uniquely designed parts tailored to meet the specific requirements of industrial applications. Unlike standardized components, these parts are engineered to fit particular dimensions, materials, and performance specifications, making them indispensable for industries like aerospace, automotive, medical, electronics, and heavy machinery. These components ensure seamless integration into complex systems, boosting efficiency, reliability, and performance.

Custom components can range from simple geometries to intricate designs, serving diverse purposes such as connectors, housings, brackets, gears, and more. The customization process often involves advanced manufacturing techniques to ensure precision, quality, and adherence to exacting tolerances.

Why Should Custom Industrial Components Use 5-Axis CNC Machining?

5-axis CNC machining has revolutionized the production of custom industrial components by offering unparalleled precision, efficiency, and versatility. Here are the primary reasons why it is the preferred choice:

- Enhanced Design Flexibility

- 5-axis CNC machines can move cutting tools along five different axes simultaneously, allowing for the creation of complex geometries that would be impossible or inefficient using traditional machining methods.

- High Precision and Accuracy

- The technology ensures tight tolerances and accurate dimensions, critical for components used in high-stakes industries like aerospace and medical devices.

- Reduced Setup Time

- Unlike 3-axis machines, which may require multiple setups and repositioning, 5-axis machines complete intricate tasks in a single setup. This minimizes errors and boosts production speed.

- Improved Surface Finishes

- The simultaneous movement of axes enables smoother and more consistent surface finishes, reducing the need for extensive post-processing.

- Efficient Material Utilization

- By allowing complex cuts and angles, 5-axis machining minimizes material waste, making it a cost-effective solution for producing high-quality parts.

Precautions for Custom Industrial Components Using 5-Axis CNC Machining

To ensure optimal outcomes, several precautions should be taken:

- Thorough Design Planning

- Collaborate with skilled engineers to create detailed CAD models, ensuring that the design is optimized for 5-axis machining capabilities.

- Material Selection

- Choose materials that align with the component’s intended application, considering factors like strength, weight, and thermal resistance.

- Tool Selection

- Use high-quality cutting tools suited for the material and design to prevent wear and achieve precision.

- Machine Calibration

- Regularly calibrate the CNC machine to maintain accuracy and prevent errors due to misalignment.

- Simulation and Testing

- Employ machining simulations to identify potential issues before actual production, reducing risks of material wastage and machine damage.

- Operator Expertise

- Ensure operators are adequately trained in 5-axis CNC machining to handle complex projects efficiently.

Advantages of Custom Industrial Components Using 5-Axis CNC Machining

- Increased Productivity

- The ability to complete complex machining tasks in a single setup significantly boosts production efficiency.

- Versatility

- Handles a wide range of materials, including metals, plastics, and composites, making it suitable for various industries.

- Cost Savings

- Reduced material waste, fewer setups, and minimized post-processing translate to overall cost efficiency.

- Shorter Lead Times

- Streamlined processes enable quicker turnaround times for prototypes and production runs.

- Improved Component Quality

- Achieves superior accuracy, ensuring components meet stringent industry standards.

Benefits of Custom Industrial Components Using 5-Axis CNC Machining

- Optimized Performance

- Components tailored to specific applications ensure seamless integration and enhanced functionality.

- Scalability

- Ideal for both low-volume prototypes and high-volume production, offering flexibility for manufacturers.

- Innovation

- Encourages the development of innovative designs, pushing the boundaries of traditional manufacturing.

- Sustainability

- Efficient material utilization and reduced waste contribute to environmentally friendly production practices.

Why Choose Great Light for 5-Axis CNC Machining?

As a professional supplier of custom industrial components, Great Light leverages state-of-the-art 5-axis CNC machining equipment and expertise to deliver exceptional results. Here’s why Great Light is the ideal partner for your manufacturing needs:

- Advanced Technology: Cutting-edge 5-axis CNC machines capable of producing highly complex parts with precision.

- Comprehensive Services: One-stop solutions, including design, machining, and post-processing services.

- Material Expertise: Proficiency in working with diverse materials such as stainless steel, aluminum alloy, and titanium alloy.

- Customization: Tailored solutions to meet unique requirements across various industries.

- Competitive Pricing: High-quality components at the best prices, ensuring value for investment.

Conclusion

Custom industrial components play a vital role in modern manufacturing, and 5-axis CNC machining is the gold standard for producing these parts. With its unmatched precision, efficiency, and versatility, 5-axis CNC machining is the preferred choice for industries seeking innovative and reliable solutions. Trust Great Light to deliver high-quality custom components tailored to your needs. Start customizing your industrial components today and experience the benefits of advanced manufacturing technologies.