Advanced CNC Machining Service Provider – Great Light

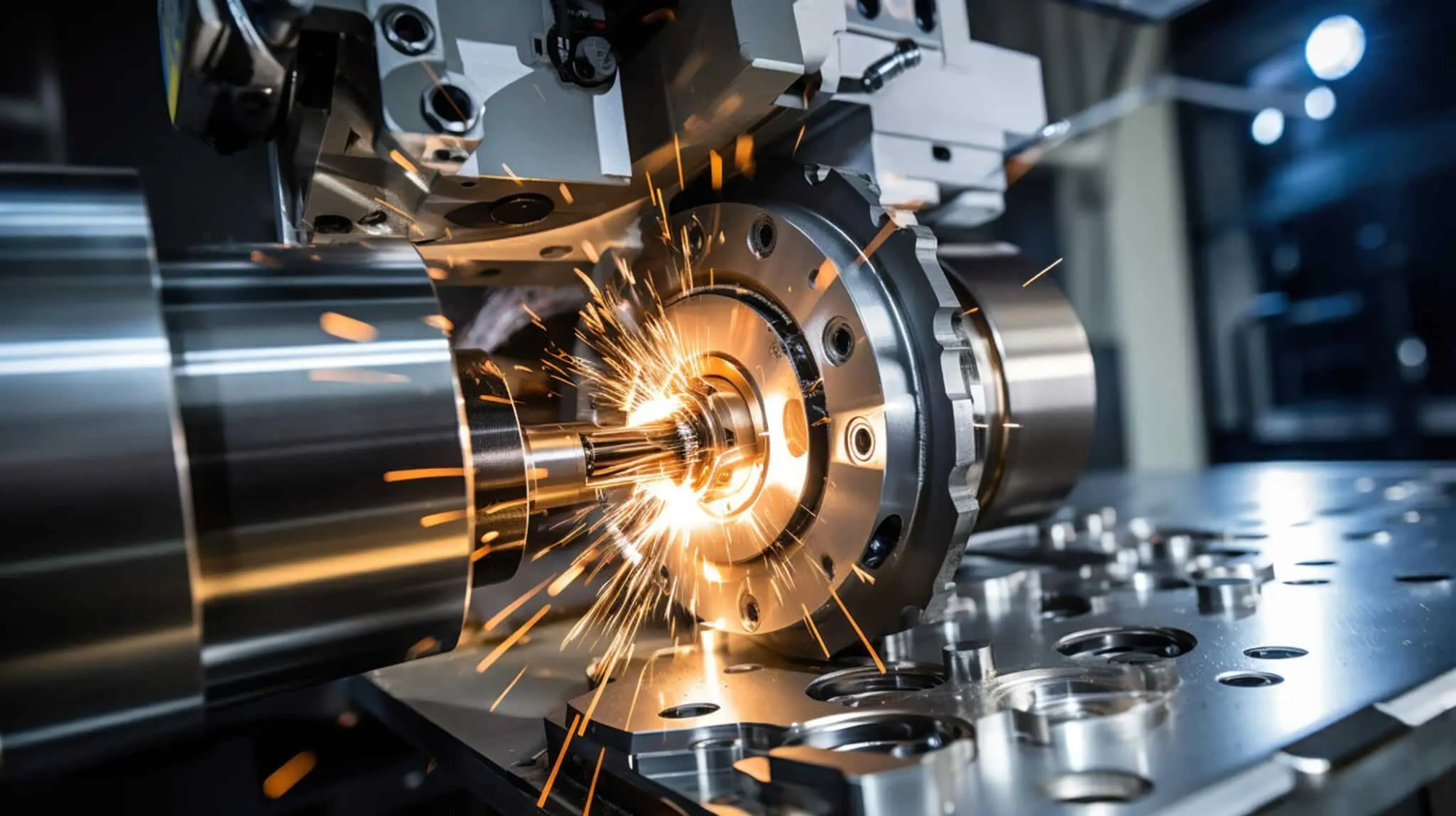

Introduction to Advanced CNC Machining

Advanced CNC machining refers to the use of computer numerical control (CNC) machines equipped with cutting-edge technology to fabricate highly complex and precise parts from a wide range of materials. It goes beyond standard CNC machining by incorporating multi-axis systems, automated tool changes, and adaptive programming. This technology enables the production of components with intricate geometries, tight tolerances, and superior surface finishes, catering to industries with demanding requirements such as aerospace, medical, automotive, and electronics.

What Sets Advanced CNC Machining Apart?

Precision and Complexity

Advanced CNC machining can achieve tolerances as tight as ±0.001 mm, allowing for the production of parts with intricate features and impeccable accuracy.

Material Versatility

From metals like titanium and stainless steel to engineering plastics and composites, this process accommodates diverse materials for various industrial applications.

Scalability

Whether for prototyping or mass production, advanced CNC machining ensures consistent quality at every scale.

Automation and Efficiency

Integrated automation reduces production time and costs, making it ideal for high-precision industries with stringent timelines.

Features of Advanced CNC Machining

| Feature | Description |

|---|---|

| Multi-Axis Capability | Enables 3-, 4-, and 5-axis machining for greater design freedom and complexity. |

| Precision Tolerances | Achieves tight tolerances to meet critical industry standards. |

| Wide Material Support | Works with metals, plastics, composites, and exotic alloys. |

| Automation Integration | Reduces manual intervention, enhancing repeatability and productivity. |

| Tool Versatility | Offers multiple tool types for cutting, drilling, milling, and engraving. |

Materials and Sizes Processed by Advanced CNC Machining

| Material | Common Applications | Advantages | Typical Sizes |

|---|---|---|---|

| Aluminum | Aerospace components | Lightweight, corrosion-resistant | Up to 2m x 1m |

| Stainless Steel | Medical instruments | Durable, high strength | Up to 1.5m x 1m |

| Titanium | Aerospace, medical implants | High strength-to-weight ratio | Up to 1m x 1m |

| Engineering Plastics | Electronic enclosures, prototypes | Lightweight, insulating | Customizable, typically smaller sizes |

| Brass | Decorative and functional parts | Easy to machine, excellent conductivity | Up to 1m x 1m |

Advantages of Advanced CNC Machining Services

- Unmatched Precision

Advanced CNC machining ensures each part meets exact specifications, crucial for industries like aerospace and healthcare. - Reduced Lead Time

Automated processes and efficient programming reduce production times for both prototyping and large-scale manufacturing. - Cost-Effectiveness

Minimizing waste and rework reduces costs while delivering high-quality results. - Design Freedom

With multi-axis machining, even the most intricate designs can be brought to life. - Material Flexibility

From tough metals to lightweight plastics, advanced CNC machining supports a wide array of materials.

Industries Benefiting from Advanced CNC Machining

| Industry | Applications |

|---|---|

| Aerospace | Engine components, structural parts, and custom fixtures |

| Medical | Surgical tools, implants, and diagnostic equipment components |

| Automotive | High-performance engine parts, custom prototypes, and precision fixtures |

| Electronics | Housings, heat sinks, and connectors for high-tech devices |

| Defense | Custom weaponry, surveillance components, and ruggedized hardware |

| Energy | Components for wind turbines, oil drilling equipment, and nuclear reactors |

| Robotics | Custom frames, joints, and complex robotic assemblies |

10 Representative Companies Offering Advanced CNC Machining Services in the Market

| Company | Service Areas | Advantages | Disadvantages | Equipment |

|---|---|---|---|---|

| Great Light | Aerospace, medical, automotive | High precision, fast turnaround | Limited regional coverage | 5-axis CNC machines |

| Protolabs | Prototyping, custom manufacturing | Fast prototyping, online quoting | Expensive for low-volume orders | Multi-material support |

| Xometry | Global manufacturing network | Wide material selection, scalability | Quality may vary across partners | 3D and CNC integration |

| Hubs | Custom parts on demand | Ease of access to global suppliers | Limited local customization | Various CNC types |

| Fictiv | Rapid prototyping and production | Fast production times | Premium pricing | High-precision CNCs |

| Rapid Direct | Prototyping and small-batch runs | Competitive pricing | Less focus on large-scale orders | CNC, injection molding |

| Schunk | Industrial and robotic components | Specializes in gripping systems | Focused on niche applications | High-tech CNC machines |

| Caron Precision | Aerospace and medical devices | Expertise in tight tolerances | Longer lead times | Advanced 5-axis CNC |

| APC Machining | Oil & gas, aerospace industries | Expertise in high-strength materials | Limited scalability | Heavy-duty CNC machines |

| Fox Valley Tool | Tool and die manufacturing | Expert custom tooling | Geographically limited service | Large-scale CNC setups |

Great Light: A Leader in Advanced CNC Machining Services

Why Choose Great Light?

- State-of-the-Art Equipment: Our 5-axis CNC machines ensure precision and complexity in every component.

- Experienced Team: Decades of expertise in manufacturing across various industries.

- Versatile Material Processing: From lightweight aluminum to robust titanium, we cover it all.

- One-Stop Solutions: From initial design to post-processing, we handle the entire manufacturing process.

Order Your Advanced CNC Machining Components Today!

Conclusion

As industries evolve, the demand for precision-engineered components continues to grow. Advanced CNC machining has proven to be a cornerstone technology, enabling unparalleled precision, flexibility, and efficiency. Whether you’re developing next-generation aerospace components or crafting intricate medical devices, partnering with a trusted service provider like Great Light ensures success at every stage of the process.