5-Axis CNC Machining Services For Intricate Designs

5-Axis CNC Machining Services is revolutionizing modern manufacturing, enabling the production of highly intricate designs with unmatched precision and efficiency. This article explores the applications, processes, and benefits of 5-axis CNC machining, focusing on its role in manufacturing intricate metal products. Let’s delve into how Great Light’s state-of-the-art 5-axis CNC machining services cater to the ever-growing demand for precision and customization.

What Are the Main Product Parts That Use Intricate Designs?

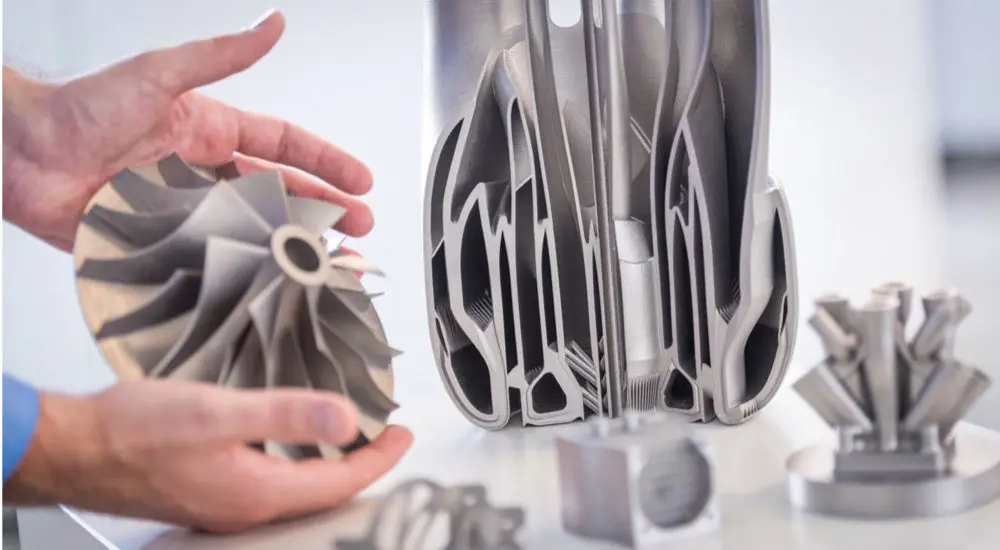

Intricate designs are crucial in several industries, as they allow the production of parts with complex geometries that meet specific functional and aesthetic requirements. Below are the main product parts utilizing intricate designs:

- Aerospace Components:

- Turbine blades, engine housings, and structural brackets.

- Medical Devices:

- Surgical instruments, implants, and diagnostic equipment parts.

- Automotive Parts:

- Engine blocks, transmission housings, and suspension components.

- Electronic Enclosures:

- Heat sinks, chassis, and connectors.

- Industrial Machinery:

- Precision gears, tool holders, and hydraulic components.

- Consumer Goods:

- Luxury watches, jewelry, and high-end audio equipment.

Why Do These Parts Use Intricate Designs?

Intricate designs are essential for the following reasons:

- Enhanced Functionality: Complex geometries often improve performance, such as optimizing airflow in turbine blades or reducing weight in aerospace components.

- Miniaturization: Many industries demand smaller yet highly functional parts, achievable only with intricate designs.

- Improved Durability: Intricate designs allow for optimized stress distribution and enhanced material utilization.

- Aesthetic Appeal: In consumer goods, intricate designs add a premium look and feel.

- Customization: Advanced designs enable the production of bespoke parts tailored to specific applications.

Main Production Processes for Intricate Design Parts

| Production Process Name | Materials Used | Main Uses | Advantages | Quantity Suitable for Customized Products |

|---|---|---|---|---|

| 5-Axis CNC Machining | Metals (Aluminum, Titanium, Steel) | Aerospace, Automotive, Medical | High precision, complex geometries, minimal waste | Suitable for low to high volumes |

| 3D Printing | Plastics, Metals, Composites | Prototyping, Medical, Consumer Goods | Rapid prototyping, design flexibility | Ideal for small batch customization |

| Die Casting | Aluminum, Zinc, Magnesium | Automotive, Electronics, Industrial Machinery | High production rates, consistent quality | Suitable for medium to high volumes |

| Vacuum Casting | Plastics, Silicone | Prototypes, Low-volume production | Cost-effective for small batches, fast tooling | Small batch customization |

| Sheet Metal Processing | Stainless Steel, Aluminum | Enclosures, Panels, Structural Parts | Durable, versatile, economical | Low to high volumes |

| Injection Molding | Plastics | Consumer Electronics, Medical Devices | High repeatability, cost-effective for mass production | Medium to high volumes |

Advantages of 5-Axis CNC Machining Services for Intricate Designs

- Unmatched Precision: Achieve tolerances as tight as ±0.001 mm, ensuring components meet exact specifications.

- Enhanced Efficiency: Reduce setup time by machining complex parts in a single operation.

- Versatility: Accommodates a wide range of materials, including metals and composites.

- Superior Surface Finish: Eliminates the need for extensive post-processing, delivering high-quality finishes.

- Flexibility: Ideal for producing prototypes and low-volume customized products.

- Cost-Effective: Reduces material waste and speeds up production timelines.

- Complex Geometries: Easily creates intricate designs that are impossible with traditional machining methods.

Why Choose Great Light for 5-Axis CNC Machining Services?

As a leading supplier of 5-axis CNC machining services, Great Light leverages advanced equipment and cutting-edge technology to address the challenges of manufacturing intricate metal products. Here’s why Great Light stands out:

- Comprehensive Capabilities: From design to production and post-processing, Great Light offers a one-stop solution.

- Material Expertise: Process nearly all metal materials, including stainless steel, aluminum alloy, titanium alloy, and mold steel.

- Customization: Tailored solutions for unique customer requirements.

- Affordable Pricing: Competitive rates without compromising quality.

- Fast Turnaround: Streamlined processes ensure timely delivery.

Customize Your Intricate Designs Metal Products Today

Great Light is dedicated to solving complex manufacturing problems with unparalleled precision and efficiency. Whether you need intricate aerospace components, medical devices, or custom consumer goods, Great Light’s 5-axis CNC machining services offer the perfect solution. Contact us now to discuss your project and get the best pricing for your custom intricate designs metal products!