5-Axis CNC Machining Services for Complex Metal Parts: A Comprehensive Guide

Introduction

In today’s manufacturing landscape, precision and efficiency are paramount, especially when producing complex metal parts. One of the most advanced techniques for achieving this level of accuracy is 5-axis CNC machining. This post will explore the significance of 5-axis CNC machining services, the main types of complex metal parts, the challenges faced, and the advantages offered by this technology. As an experienced Custom Complex Metal Parts Supplier, Great Light offers innovative solutions using 5-axis CNC machining to ensure exceptional quality and precision.

What are the Main Types of Complex Metal Parts?

Complex metal parts are components that require high precision and are typically used in industries like aerospace, automotive, medical devices, electronics, and more. They often feature intricate geometries, multiple surfaces, and tight tolerances that traditional manufacturing methods struggle to achieve.

Common Types Include:

- Aerospace Components: Aircraft engine parts, landing gear, fuselage components

- Automotive Parts: Engine components, custom body parts, gear housings

- Medical Devices: Surgical instruments, implants, medical equipment housings

- Electronics Components: Heat sinks, connectors, casings for electronic devices

- Tooling: Dies, molds, jigs, and fixtures used in mass production

Common Application Scenarios for Complex Metal Parts

The industries that rely heavily on complex metal parts include:

- Aerospace: Components such as turbine blades, nozzles, and brackets are critical in ensuring flight safety and performance.

- Automotive: From engine blocks to exhaust systems, complex metal parts are essential for improving vehicle efficiency and durability.

- Medical Devices: Precision parts are used for implants and surgical tools, where accuracy can mean the difference between success and failure.

- Electronics: Heat dissipation solutions like heatsinks are fabricated using intricate designs to optimize device performance.

- Energy: Components for power generation systems, such as turbine blades, are made from advanced alloys for enhanced performance under extreme conditions.

Introduction to Material Properties of Common Metal Parts

When manufacturing complex metal parts, the choice of material is critical. Different materials possess unique properties that make them suitable for specific applications.

Common Materials Include:

- Stainless Steel: Known for its corrosion resistance and high strength, making it ideal for aerospace and medical applications.

- Aluminum Alloys: Lightweight, non-corrosive, and easy to machine, often used in automotive and electronics industries.

- Titanium Alloys: Lightweight and strong, with excellent corrosion resistance, titanium is used in aerospace and medical implants.

- Mold Steel: Often used in tooling and die-casting, offering excellent wear resistance.

Material Properties (Tensile Strength, Yield Strength, Hardness)

- Tensile Strength (MPa): The maximum stress a material can withstand while being stretched or pulled before breaking.

- Yield Strength (MPa): The stress at which a material begins to deform plastically.

- Elongation After Fracture (%): A measure of a material’s ability to deform before breaking.

- Hardness (HBC): A material’s resistance to deformation, particularly indentation, useful for determining wear resistance.

Features and Applications of Complex Metal Parts

Features:

- High Precision: CNC machining, especially 5-axis machining, ensures extremely tight tolerances, often down to microns.

- Complex Geometries: Ability to machine intricate designs with undercuts, angles, and features impossible for traditional methods.

- Material Versatility: Capability to work with a variety of materials, from metals to advanced alloys.

Applications:

- Customization: Tailored designs for unique needs across industries like aerospace, automotive, and medical.

- Tooling and Prototyping: Fast and accurate production of molds, dies, and prototypes, helping businesses minimize time-to-market.

Advantages of 5-Axis CNC Machining Services for Complex Metal Parts

1. Precision and Accuracy

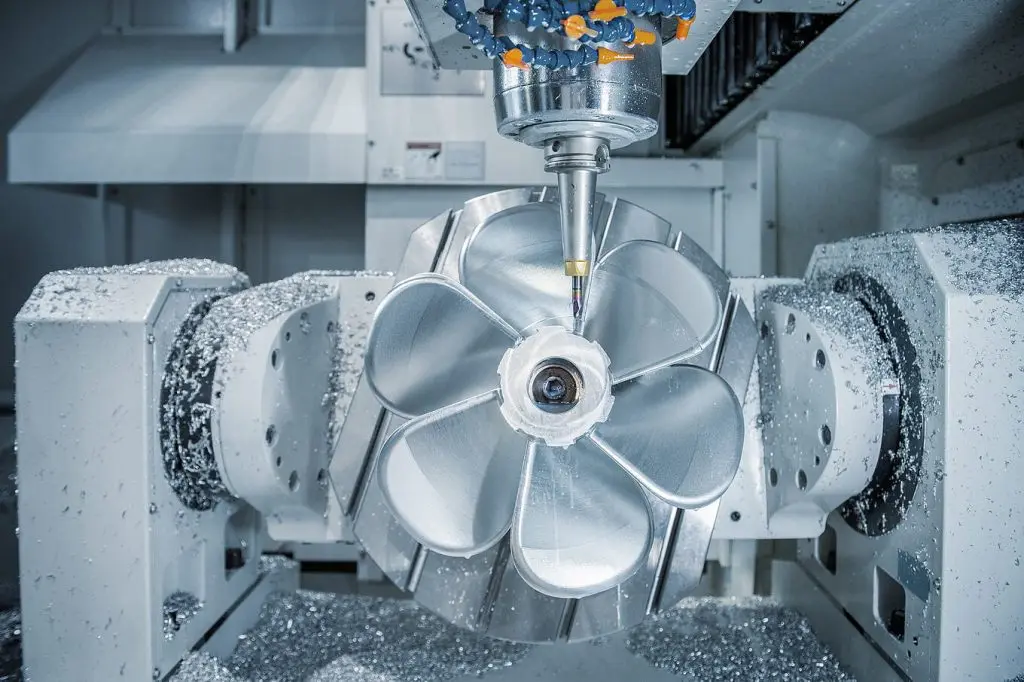

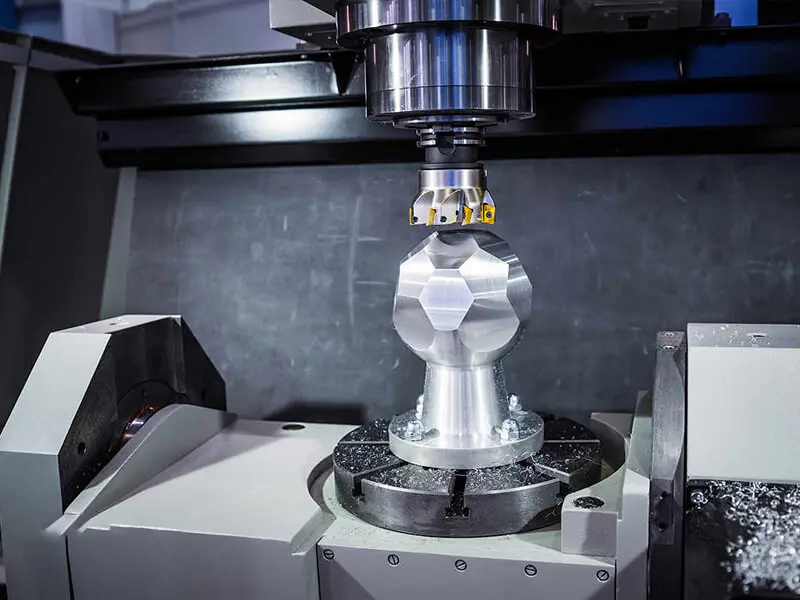

- 5-axis CNC machining allows the machine to move across five different axes, which means it can cut complex parts from multiple angles without repositioning the workpiece. This results in high precision and reduces errors, making it ideal for creating complex geometries.

2. Flexibility in Design

- The ability to manipulate the part from multiple angles makes 5-axis CNC machining versatile. It allows the creation of parts that would otherwise require multiple setups, saving time and labor costs.

3. High-Speed Production

- Unlike traditional methods, 5-axis CNC machining provides quicker turnaround times for complex parts. The ability to machine several faces of a part in one setup reduces the need for secondary processes.

4. Increased Tool Life

- Tools are kept in a more optimal cutting position, which extends their lifespan and reduces the need for frequent tool changes.

5. Reduced Human Error

- Automated machining reduces human error, ensuring parts are produced with consistent quality, even in high-volume production.

6. Capability to Machine Complex Geometries

- From aerospace components to medical device parts, 5-axis CNC machining can produce intricate geometries that other manufacturing processes cannot achieve.

Difficulties of 5-Axis CNC Machining Services for Complex Metal Parts

Despite its many advantages, 5-axis CNC machining presents several challenges:

- Complex Programming: Operating a 5-axis machine requires specialized knowledge and software to ensure precise cutting paths, making programming more complex compared to traditional CNC machines.

- Machine Cost: The cost of 5-axis CNC machines is significantly higher than that of 3-axis machines. This investment is reflected in the pricing of services.

- Material Waste: Complex parts with intricate geometries may result in material waste, especially when certain areas are cut away to achieve the desired shape.

- Tooling Costs: Specialized tools are required for certain materials or designs, which can add to the production cost.

Great Light: Your Expert in Custom Complex Metal Parts Manufacturing

At Great Light, we understand the challenges and complexities of manufacturing custom metal parts. With our advanced 5-axis CNC machining equipment and high-quality production technology, we ensure that all parts meet the precise specifications required by industries like aerospace, automotive, medical, and electronics.

Our team of experts works closely with clients to deliver:

- Custom Design: Tailor-made solutions to meet unique design and performance requirements.

- One-stop Services: In addition to 5-axis CNC machining, we offer post-processing services, including finishing, polishing, anodizing, and coating.

- Rapid Turnaround: We use our 5-axis CNC machining technology to provide fast prototyping and production runs.

At Great Light, we are committed to providing the highest quality custom complex metal parts at competitive prices. Whether you need a single prototype or a large production run, we can meet your needs with precision and efficiency.

Conclusion

5-Axis CNC Machining Services is an invaluable tool for producing complex metal parts that require precision and intricate geometries. Great Light’s expertise and advanced equipment allow us to deliver high-quality, cost-effective solutions to meet the demanding needs of industries ranging from aerospace to medical devices.

If you’re looking for reliable custom complex metal parts suppliers with cutting-edge capabilities, contact Great Light to learn how we can help you with your next project.