5-Axis CNC Machining for Precision Die-Cast Molds

What are Die-Cast Molds?

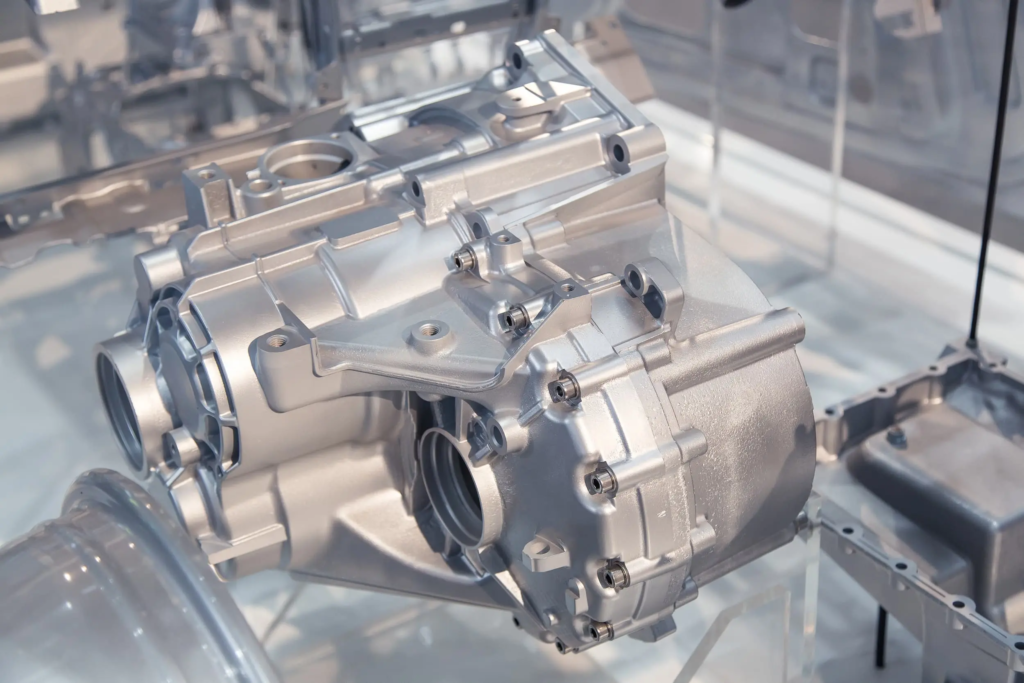

Die-cast molds are specialized tools used in the die-casting manufacturing process to create metal components with intricate shapes and tight tolerances. These molds, often made from hardened steel or other durable materials, are designed to withstand the high-pressure injection of molten metal. The molten material solidifies within the mold cavity, forming a precise, high-quality part that can be used in industries like automotive, aerospace, electronics, and more.

Die-cast molds typically consist of two primary sections: the cavity side and the core side. The cavity side forms the outer shape of the part, while the core side shapes the internal features. These molds may also include complex features such as cooling channels, ejector pins, and sliders, which enable the creation of detailed components efficiently.

Why Do Die-Cast Molds Have to Be Precision?

Precision is paramount in die-cast molds because:

- Product Quality: The accuracy of a mold directly impacts the dimensional consistency and surface finish of the final product. High precision ensures the components meet design specifications and perform optimally.

- Minimized Defects: Precision molds reduce common casting defects like flash, porosity, and dimensional inaccuracies, improving overall product reliability.

- Cost-Effectiveness: Precision molds decrease material waste, minimize the need for secondary operations, and improve production efficiency, leading to significant cost savings.

- Extended Mold Life: Well-made molds experience less wear and tear, ensuring a longer lifespan and reducing the frequency of replacements.

- Compatibility with High-Volume Production: Precision molds ensure consistency across thousands or even millions of parts, essential for industries requiring large-scale production.

Precautions for Making Precision Die-Cast Molds

Creating precision die-cast molds requires meticulous planning and execution. Here are some precautions:

- Material Selection: Choose high-grade tool steels or alloys with excellent wear resistance and thermal conductivity to handle the high pressures and temperatures of die-casting.

- Design Considerations: Optimize the mold design for uniform cooling, efficient metal flow, and proper venting to prevent defects.

- Dimensional Accuracy: Use advanced measurement tools to verify that the mold dimensions match the design specifications.

- Thermal Management: Integrate cooling channels to maintain temperature control and prevent thermal fatigue.

- Regular Maintenance: Implement a maintenance schedule to clean, inspect, and repair molds, ensuring they remain in top condition.

- Precision Machining: Utilize high-precision machining techniques, like 5-axis CNC machining, to achieve the required tolerances and surface finishes.

Advantages of 5-Axis CNC Machining for Precision Die-Cast Molds

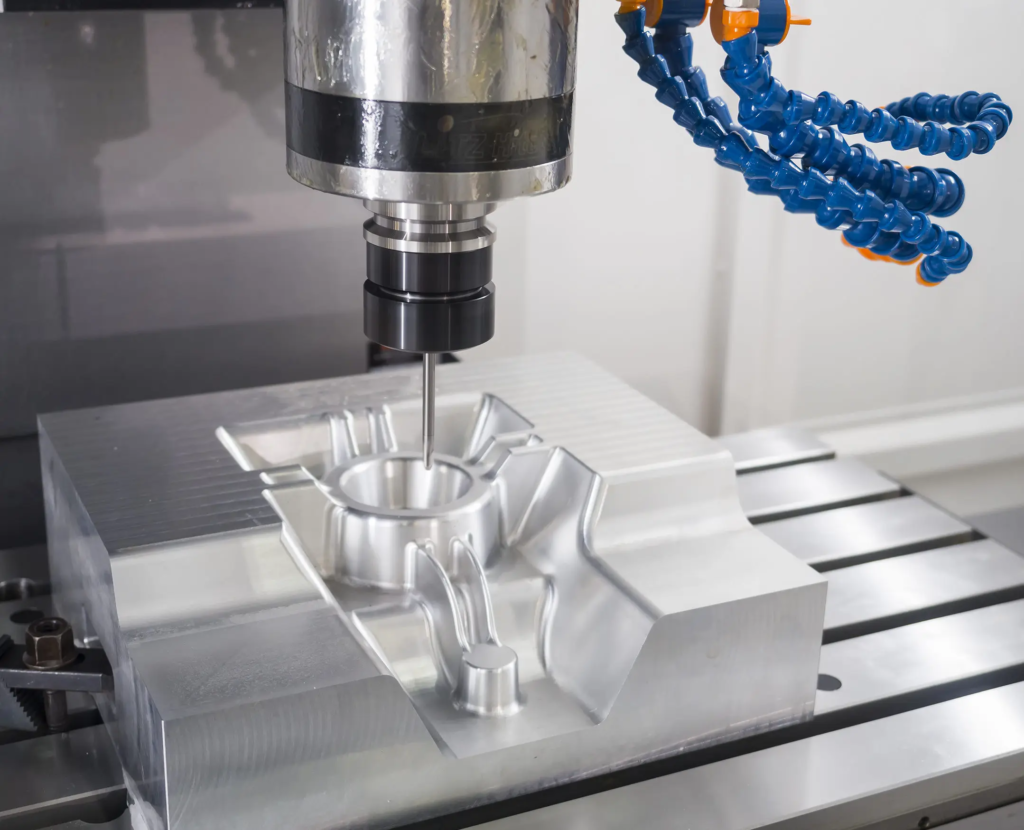

5-axis CNC machining is a game-changer in manufacturing precision die-cast molds. Its advantages include:

- Enhanced Geometric Flexibility: With the ability to move along five axes simultaneously, 5-axis CNC machines can create intricate and complex mold shapes that are difficult or impossible with traditional 3-axis machines.

- Improved Accuracy: By reducing the need for multiple setups, 5-axis machining minimizes errors caused by repositioning, ensuring higher dimensional accuracy.

- Time Efficiency: The reduced number of setups shortens production time, making the process faster and more efficient.

- Superior Surface Finish: Advanced toolpaths and continuous cutting motions result in smoother surfaces, reducing the need for extensive post-processing.

- Cost-Effectiveness: While the initial investment in 5-axis machines is higher, their efficiency, accuracy, and versatility significantly reduce overall production costs.

- Versatility in Materials: 5-axis machining can handle a wide range of materials, from aluminum and titanium alloys to hardened steels, making it ideal for various mold applications.

Benefits of 5-Axis CNC Machining for Precision Die-Cast Molds

- Consistency Across Large Batches: Ensures uniformity across thousands of parts, which is crucial for industries like automotive and aerospace.

- Shortened Lead Times: Faster machining speeds and fewer setups result in quicker production cycles, enabling faster time-to-market.

- Innovation in Mold Design: Allows designers to incorporate advanced features such as complex cooling channels and detailed textures, enhancing mold functionality and performance.

- Reduced Material Waste: Precise machining reduces scrap material, contributing to sustainability and cost savings.

- Increased Productivity: By automating complex machining tasks, 5-axis CNC machines free up resources for other operations, boosting overall productivity.

Great Light: Your Trusted Partner for Precision Die-Cast Molds

As a professional custom precision die-cast mold supplier, Great Light specializes in solving complex manufacturing challenges with state-of-the-art 5-axis CNC machining technology. Our advanced equipment and expertise enable us to deliver:

- Tailored Solutions: We provide customized molds that meet the specific needs of diverse industries.

- Comprehensive Services: From design to post-processing, we offer one-stop solutions for all your mold-making requirements.

- High-Quality Materials: We work with a wide variety of materials, ensuring the best fit for your application.

- Competitive Pricing: Our efficient processes and advanced machinery allow us to offer precision molds at competitive prices.

Customize Your Precision Die-Cast Molds Today

Experience the benefits of precision and efficiency with Great Light’s 5-axis CNC machining services. Whether you’re looking to enhance product quality, reduce production costs, or shorten lead times, we have the expertise and technology to help you achieve your goals. Customize your precision die-cast molds with us today and take the first step toward manufacturing excellence.