5-Axis CNC Machining for Complex Aerospace Designs

What is Complex Aerospace Design?

Complex aerospace design refers to the intricate and precise engineering of components used in the aerospace industry. These designs often incorporate advanced geometries, lightweight materials, and stringent performance criteria. Aerospace designs must meet rigorous standards to ensure safety, durability, and efficiency in extreme environments, such as high altitudes, rapid speeds, and varying temperatures.

Examples of complex aerospace designs include turbine blades, airframes, and satellite components. These parts demand precision engineering due to their critical role in performance and safety.

What Aerospace Parts are Complexly Designed?

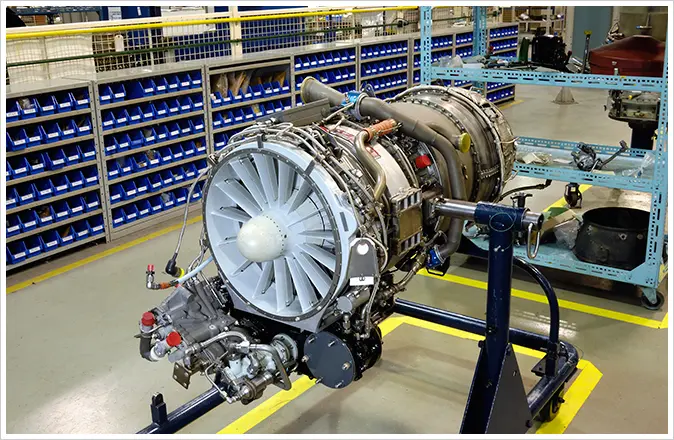

1. Turbine Blades and Engine Components

Turbine blades and engine components require high precision to function efficiently. Their complex geometries optimize airflow and withstand extreme temperatures and pressures within jet engines.

2. Airframes

Airframes consist of lightweight yet strong structures that must endure aerodynamic forces. Their complex designs involve intricate shapes and lightweight materials, such as titanium alloys and composites.

3. Landing Gear Components

Landing gear components are subject to heavy stress and require precise manufacturing to handle repeated load cycles. The parts must meet strict safety requirements and durability standards.

4. Avionics Housings

Avionics housings protect sensitive electronic systems. These components require high precision to ensure proper shielding and alignment.

5. Satellite and Spacecraft Parts

Components for satellites and spacecraft, such as antennae and structural frames, involve intricate designs to ensure functionality in the vacuum of space.

Why Should Complex Aerospace Designs Be Made with 5-Axis CNC Machining?

5-Axis CNC machining is ideal for manufacturing complex aerospace designs due to its precision, efficiency, and ability to handle challenging geometries. Below are key reasons:

1. Enhanced Precision

5-Axis CNC machines allow simultaneous movement along five axes, enabling precise machining of intricate geometries. This accuracy is crucial for components like turbine blades and engine parts.

2. Reduced Setup Time

The ability to machine multiple faces of a part in a single setup minimizes errors caused by repositioning, improving consistency and reducing production time.

3. Support for Complex Geometries

5-Axis CNC machines excel at machining curved surfaces and intricate angles that are difficult or impossible to achieve with traditional methods.

4. Improved Surface Finish

The continuous movement of the cutting tool enhances surface finish, a vital requirement for aerospace parts to ensure optimal performance and durability.

5. Material Versatility

5-Axis CNC machining can handle aerospace-grade materials like titanium, aluminum alloys, and composites, which are often difficult to machine.

What are the Precautions for 5-Axis CNC Machining for Complex Aerospace Designs?

To achieve optimal results, the following precautions should be considered:

1. Proper Tool Selection

Selecting the right cutting tools, coatings, and tool paths is essential to minimize wear and ensure precision when machining aerospace-grade materials.

2. Machine Calibration

Regular calibration of the CNC machine ensures accuracy and repeatability. Precision is non-negotiable in aerospace manufacturing.

3. Cutting Parameters

Adjusting cutting speeds, feeds, and depths based on material properties prevents tool wear and ensures a smooth machining process.

4. Thermal Management

Using coolants effectively prevents heat buildup, which could compromise material integrity and dimensional accuracy.

5. Quality Assurance

Conducting rigorous inspections during and after machining ensures that parts meet aerospace industry standards.

Advantages of 5-Axis CNC Machining for Complex Aerospace Designs

1. Increased Efficiency

5-Axis CNC machining reduces production time and material waste by minimizing setups and tool changes.

2. Flexibility

The capability to machine a wide range of complex shapes makes 5-axis machining suitable for various aerospace components.

3. Higher Productivity

Simultaneous movement along multiple axes allows faster production cycles, meeting tight deadlines without compromising quality.

4. Superior Accuracy

The advanced control systems in 5-Axis CNC machines ensure consistent precision across multiple parts.

Benefits of 5-Axis CNC Machining for Complex Aerospace Designs

1. Cost Savings

Reduced material waste and faster production times lower overall manufacturing costs.

2. Quality Assurance

Consistent accuracy and high-quality finishes ensure parts meet strict aerospace standards.

3. Design Freedom

Engineers can design innovative and intricate components without worrying about manufacturing limitations.

4. Global Competitiveness

Adopting advanced machining techniques keeps manufacturers competitive in the global aerospace industry.

As a professional Custom Industrial Components Supplier, Great Light relies on advanced 5-Axis CNC machining equipment and cutting-edge production processes to address complex manufacturing challenges. With a commitment to precision and quality, Great Light offers one-stop post-processing and finishing services, making it the first choice for custom industrial components.

Customize Your Industrial Components Today

Leverage Great Light’s expertise in 5-Axis CNC machining for aerospace applications. Contact us now to ensure top-quality, cost-effective solutions tailored to your needs.